Understanding Supply Chain Visibility (SCV) in 2025

At times like this where supply chains are facing one disruption after another, visibility is more critical for global supply chains than ever. A more visible supply chain yields many advantages for a business, from preparedness for disruption to keeping…

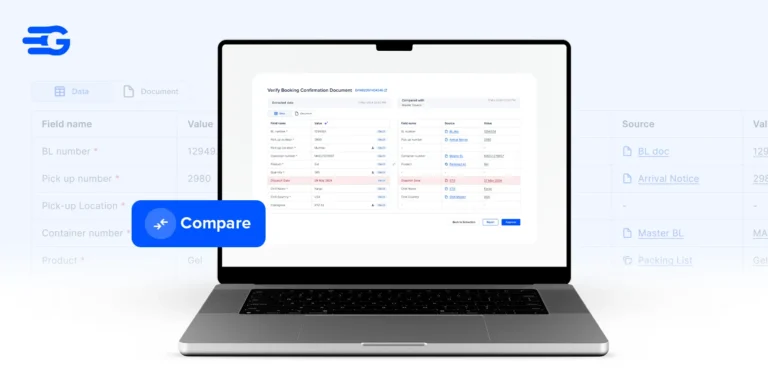

Understanding Invoice Matching: Types, Processes, and Best Practices

Most logistics companies are drowning in paperwork. Bills from trucking companies don’t match the original quotes.…

Top 10 Supply Chain Traceability Software Solutions in 2025

Supply chains are getting more complicated, and companies can’t afford to lose track of their products…

Commercial Invoice vs Pro forma Invoice: What’s the Difference

Most people in logistics know about commercial invoices and proforma invoices, but there’s still confusion about…

Purchase Order vs Invoice: What’s the difference?

Look, if you’re running trucks, managing warehouses, or dealing with suppliers daily, you’ve probably gotten burned…

Common Invoice Discrepancy List and How to Fix Them Quickly

Invoice errors are a nightmare for logistics companies. Between freight charges, fuel surcharges, and accessorial fees,…

Difference Between Commercial Invoice and Invoice

Paperwork mix-ups in logistics can be expensive. One common mistake is using the wrong type of…