Supply Chain Costs: A Definitive Guide for 2025

Managing supply chain costs effectively is crucial for businesses navigating the evolving landscape of 2025. Rising economic uncertainties, technological advancements, and increasing environmental regulations demand a strategic approach to cost management. Those who master this balance gain a significant competitive edge.

Effective cost management in the supply chain drives profitability and boosts competitive advantage. By understanding cost drivers and employing optimization strategies, companies can achieve sustainable growth even amid challenges. As businesses expand globally and operate in increasingly interconnected markets, managing costs becomes not just a necessity but a vital component of long-term success.

Understanding Supply Chain Costs

Supply chain costs encompass all expenses incurred throughout the supply chain process, from sourcing raw materials to delivering finished products. These costs significantly impact operational efficiency and overall business profitability. Understanding the full scope of these expenses enables businesses to make informed decisions, streamline operations, and enhance their financial health.

Key Components

- Procurement Costs: Expenses related to sourcing raw materials and services, including supplier management, contract negotiations, quality control, and compliance measures. Inadequate procurement strategies can lead to excessive costs and supply chain disruptions.

- Production Costs: Costs incurred during the manufacturing process, such as labor, materials, equipment maintenance, and utility expenses. Efficient production planning and waste minimization are essential for cost control.

- Inventory Carrying Costs: Expenses associated with storing unsold goods, including warehousing, insurance, taxes, and depreciation. Proper inventory management helps reduce holding costs and mitigates risk.

- Transportation and Logistics Costs: Costs involved in moving goods through the supply chain, from shipping fees to fuel surcharges, customs duties, and freight charges. Optimizing transportation routes and consolidating shipments can significantly reduce these expenses.

- Warehousing Costs: Expenses for storage facilities, labor, material handling, security, and facility maintenance. Automation in warehousing can improve efficiency and lower operational costs.

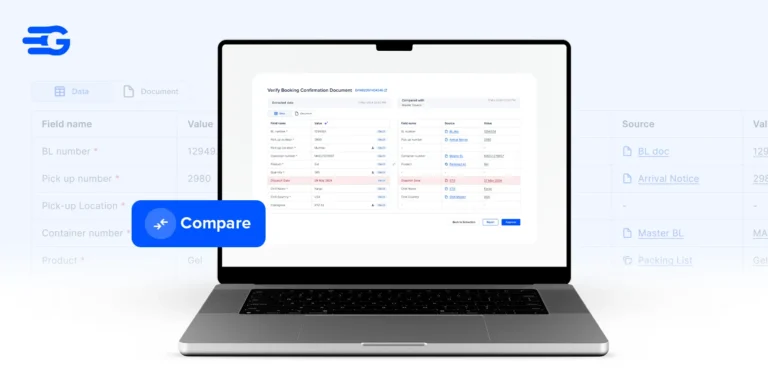

- Administrative and Overhead Costs: Indirect costs that support supply chain activities, including IT systems, human resources, compliance monitoring, and management overhead. Investing in integrated supply chain software can streamline these operations.

Emerging Challenges Impacting Supply Chain Costs in 2025

Global Economic Factors

Economic instability, driven by inflation, currency fluctuations, and shifting trade agreements, significantly affects supply chain expenses. Unstable markets and geopolitical tensions can lead to unexpected cost surges, making dynamic cost management essential.

Regulatory Changes

New tariffs, evolving trade policies, and stricter compliance requirements continue to reshape cost structures, demanding agile financial planning and comprehensive risk management. Companies must stay updated with local and international regulations to mitigate compliance-related costs.

Technological Advancements

Integrating automation and AI reduces labor costs but requires significant upfront investments. Technologies like IoT, robotics, and predictive analytics offer long-term savings but need careful planning and change management to maximize ROI.

Environmental and Sustainability Concerns

Implementing green initiatives and adhering to environmental regulations increase upfront costs but can reduce operational expenses over time. Sustainable practices, such as using renewable energy and optimizing packaging, also enhance brand value and customer loyalty.

Strategies for Optimizing Supply Chain Costs

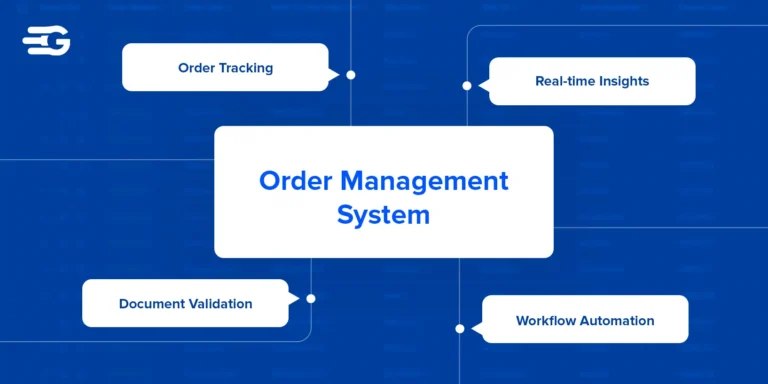

Implementing Advanced Technologies

Using AI, machine learning, blockchain, and IoT enhances efficiency, reducing human error and streamlining operations. Predictive analytics can forecast demand accurately, reducing surplus and associated costs.

Enhancing Supplier Collaboration

Building strong supplier relationships improves negotiation power and reduces procurement costs. Joint innovation and shared risk management strengthen long-term partnerships and cost predictability.

Adopting Lean Inventory Practices

Implementing just-in-time (JIT) inventory management minimizes holding costs and maximizes cash flow. Reducing excess inventory also decreases waste and enhances responsiveness to market changes.

Diversifying Sourcing and Manufacturing

Reducing dependency on single suppliers mitigates risks and stabilizes costs. Multi-sourcing strategies and regional production hubs reduce vulnerabilities related to geopolitical shifts.

Utilizing Data Analytics

Accurate demand forecasting and data-driven decision-making improve resource allocation and reduce waste. Real-time data tracking enhances visibility, helping businesses respond promptly to disruptions.

Measuring and Monitoring Supply Chain Costs

Key Performance Indicators (KPIs)

- Cost-to-Serve Analysis: Analyzes the total cost of delivering a product to a customer, including transportation, warehousing, and customer service expenses.

- Inventory Turnover Ratio: Measures how efficiently inventory is managed and moved through the supply chain.

- Order Fulfillment Cycle Time: Assesses the speed and efficiency of order processing, helping identify bottlenecks.

Continuous Improvement

Regular reviews and audits help identify areas for cost reduction, fostering a proactive approach to cost management. Incorporating feedback from supply chain partners and conducting post-implementation reviews of optimization strategies ensure sustained improvements.

Conclusion

Effectively managing supply chain costs is more important than ever. By leveraging technology, enhancing collaboration, and adopting lean practices, businesses can maintain profitability and thrive despite challenges. Proactive, data-driven approaches and continuous learning are key to navigating the complexities of supply chain expenses in 2025.