5 Warning Signs You Need an Order Management Control Tower

Order management can turn into a real nightmare when you’re juggling multiple systems, delayed shipments, and angry customers calling every day. Most companies end up playing catch-up instead of staying ahead of problems, which kills both efficiency and customer satisfaction. When you’re constantly firefighting order issues instead of preventing them, something needs to change.

That’s where an order management control tower comes in. It gives you the bird’s eye view and control you need to actually manage orders instead of just reacting to problems. But how do you know when you’ve hit that breaking point? Let’s dive into the clear signs for order management control tower adoption that show your business is ready for this

But first, let’s understand nuts-and-bolts.

What is Order Management Control Tower

An order management control tower is a centralized digital platform that gives you complete visibility and control over your entire order fulfillment process.

It works as your command center where all order information, inventory data, shipping details, and customer communications flow together in one place. Instead of jumping between different systems to track orders, you get a single dashboard that shows everything happening across your supply chain.

This system connects all your sales channels, warehouses, suppliers, and shipping partners into one unified view.

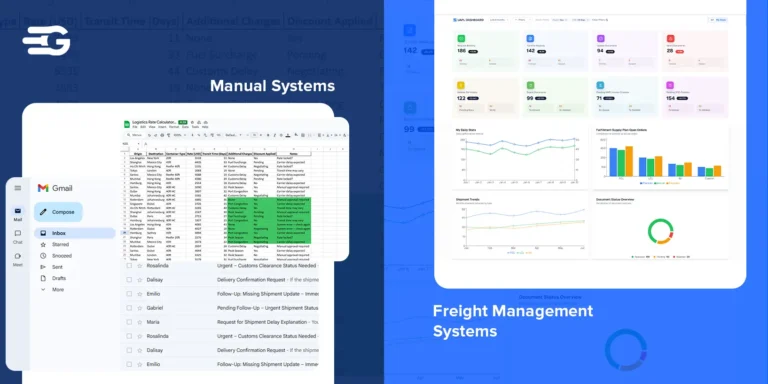

Basic Order Management vs Control Tower

| Feature | Basic Order Management | Order Management Control Tower |

| Data Sources | Limited to 2-3 systems | Integrates all channels and partners |

| Visibility | Shows order status only | Complete supply chain view |

| Decision Making | Manual and reactive | Automated and proactive |

| Problem Resolution | After issues occur | Prevents issues before they happen |

| Inventory Management | Basic tracking | Real-time optimization across locations |

| Reporting | Standard order reports | Advanced analytics and predictions |

| Scalability | Works for simple operations | Handles complex, multi-channel businesses |

5 Signs You Need an Order‑Management Control Tower

Now that you know how order management control towers are different from basic softwares, here are the signs that tell you need one.

1. You’re Manually Tracking Orders Across Multiple Spreadsheets

If your team is still using Excel sheets to manage order tracking, you’re showing clear signs for order management control tower adoption.

Manual spreadsheet management becomes a major bottleneck as your business grows, leading to countless hours of data entry, human errors, and outdated information that puts your entire operation at risk.

Here are the key problems with spreadsheet-based order tracking:

- Multiple versions of the same spreadsheet create confusion and conflicting data

- Real-time updates are impossible when different team members work on separate files

- Human errors in data entry lead to wrong shipments and frustrated customers

- No automated alerts when orders face delays or issues

- Scaling becomes impossible as order volume increases

- Integration with other systems requires constant manual imports and exports

- Historical data analysis is limited and time-consuming

When you find yourself hiring additional staff just to manage spreadsheets or when simple order lookups take several minutes, these are strong signs for order management control tower implementation.

A control tower eliminates manual tracking by automatically capturing and organizing all order data in real-time.

2. Customer Service Spends Most of Their Time Answering “Where’s My Order” Questions

When your customer service team becomes an order tracking department instead of focusing on real customer support, you’re seeing obvious signs for order management control tower necessity.

This problem is becoming super common across industries. Recent research reveals that 54% of senior executives are now investing in enhanced fulfillment processes to improve order processing speed, recognizing that slow, manual systems create customer service nightmares.

The problem gets worse when your team has to check multiple systems just to answer basic questions about order status. They’re jumping between your warehouse management system, shipping carrier websites, and inventory databases just to piece together a simple answer.

Meanwhile, customers are waiting on hold or sending multiple emails asking for updates. A control tower gives both your team and customers instant access to accurate, real-time order information, transforming customer service from reactive firefighting into proactive relationship building.

3. You’re Constantly Dealing with Stockouts While Having Excess Inventory Elsewhere

Poor inventory distribution across multiple locations creates one of the most frustrating signs for order management control tower requirement.

You’re simultaneously disappointing customers with out-of-stock messages while paying to store excess inventory in other warehouses. This imbalance directly impacts your bottom line and customer satisfaction.

| Problem | Impact | Control Tower Solution |

| Stockouts at primary location | Lost sales and frustrated customers | Automatic inventory balancing suggestions |

| Excess inventory at secondary sites | Increased storage costs and tied-up capital | Real-time redistribution recommendations |

| No visibility across locations | Poor purchasing decisions | Complete multi-location inventory dashboard |

| Manual inventory transfers | Slow response to demand changes | Automated transfer triggers and workflows |

Without centralized inventory visibility, your team makes decisions based on incomplete information. They might order more stock when plenty exists at another facility, or they might miss opportunities to fulfill orders from alternative locations.

These inefficiencies represent clear signs for order management control tower implementation that can save thousands in inventory costs while improving customer satisfaction through better product availability.

4. Orders Are Getting Lost Between Systems or Channels

When orders disappear during handoffs between your warehouse system and shipping carriers, you’re dealing with more than just technical glitches.

You’re facing customer trust issues and operational chaos.

Common order loss scenarios include:

- Orders placed during system maintenance windows that never get processed

- API failures between platforms that create data gaps

- Manual order entry errors when systems don’t communicate automatically

- Duplicate orders created when customers resubmit thinking their first order failed

- International orders that get stuck in customs processing without updates

- Wholesale orders that bypass normal processing workflows

- Return orders that don’t properly update inventory levels

These lost orders often go unnoticed until customers start complaining, creating a reactive crisis management situation.

The signs for order management control tower become obvious when you’re constantly apologizing to customers and offering expedited shipping to fix problems that shouldn’t have happened.

A control tower creates seamless data flow between all systems, ensuring no order falls through the cracks regardless of complexity or origin channel.

5. You Can’t See Real-Time Inventory Levels Across All Locations

Inventory visibility problems represent fundamental signs for order management control tower necessity that affect every aspect of your business. When you can’t instantly see what’s available across warehouses, retail stores, drop-ship partners, and third-party logistics providers, you’re making blind decisions that cost money and disappoint customers.

The lack of real-time inventory data means you’re always one step behind actual demand patterns and supply chain changes.

These operational blind spots represent clear signs for order management control tower implementation. A control tower provides instant, accurate inventory visibility across every location and channel, enabling smarter decisions and better customer experiences while reducing inventory carrying costs and stockout situations.

Companies like Missionpharma have successfully addressed these challenges. With GoComet’s control tower, they improved their internal process efficiency by 20-30% and gained better predictive capabilities for managing their supply chain operations.

How can GoComet’s Order Management Control Tower Can Help You Tackle Challenges

GoComet’s Logistics Control Tower directly tackles the signs for order management control tower implementation that businesses face every day. The platform consolidates all your order data, shipment tracking, and inventory information into one unified dashboard.

This comprehensiveness alone can solve lot of your challenges.

| Your Challenge | GoComet Solution | Key Benefits |

| Manual spreadsheet tracking | Automated order consolidation and real-time updates | Eliminates data entry errors and saves hours daily |

| Constant “where’s my order” calls | Customer portal with live tracking and proactive notifications | Reduces customer service workload by 60-80% |

| Inventory imbalances across locations | Multi-location inventory visibility and transfer recommendations | Optimizes stock levels and reduces carrying costs |

| Lost orders between systems | Unified platform with seamless API integrations | Zero order loss with complete audit trails |

| No real-time inventory visibility | Live inventory tracking across all channels and warehouses | Prevents overselling and improves availability accuracy |

| Delayed shipment notifications | Predictive alerts and automated exception management | Proactive problem resolution before customer impact |

| Poor carrier performance tracking | Comprehensive carrier analytics and performance dashboards | Data-driven carrier selection and cost optimization |

GoComet’s Gen AI capabilities take order management even further by automating document validation, predicting potential delays, and optimizing fulfillment routes.

When you’re experiencing multiple signs for order management control tower needs, GoComet provides the comprehensive solution that scales with your business growth while delivering measurable ROI through improved efficiency and customer satisfaction.

Conclusion

These five warning signs show up in businesses of all sizes, but the impact gets worse as you scale. What starts as minor inconveniences quickly becomes major operational headaches that hurt both your team’s productivity and customer relationships. The good news is that modern order management control towers can fix these problems faster than most businesses expect.

Most companies wait too long to address these signs for order management control tower needs, thinking they can manage with temporary fixes. But spreadsheets, manual processes, and disconnected systems don’t improve on their own. If you’re seeing multiple warning signs in your operation, book a demo today to explore what a centralized solution could do for your business.