What is Vendor Risk Management (VRM)? A Complete Guide

Your supply chain is only as strong as your weakest vendor. When that trucking company suddenly shuts down or your warehouse partner can’t handle holiday rush, guess who customers blame? Not them – you. The Suez Canal blockage wasn’t just bad timing; it showed how one vendor problem can torpedo entire operations.

Spotting trouble early and having backup plans ready is essential. That’s vendor risk management – knowing which suppliers could sink your business before they actually do. If you’re tired of vendor surprises derailing your operations, this guide is for you! Let’s directly dive in.

What is Vendor Risk Management?

Vendor risk management is about knowing which suppliers could kill your business before they actually do it. It’s the process of checking out vendors, monitoring their performance, and having backup plans when they fail.

It covers:

- Financial health: Are they going bankrupt next month?

- Operational capacity: Can they handle your volume?

- Compliance issues: Will they get you in legal trouble?

- Performance tracking: Are they meeting deadlines?

This means every trucking company, warehouse, freight forwarder, and technology provider gets evaluated. You’re not just hoping they’ll deliver – you’re actively watching for problems.

The point isn’t eliminating all risks. It’s about spotting trouble early and having Plan B ready. When your main carrier goes under, you switch to your backup without missing a beat. That’s vendor risk management working.

The Real Cost of Vendor Failures

When vendors fail, the bills pile up fast. Direct costs hit first – emergency freight charges, expedited shipping, and premium rates for last-minute replacements. But the real damage comes from indirect costs that keep growing long after the crisis ends.

Customer relationships take the biggest hit. Late shipping, quality issues, and broken promises don’t just cost you current orders – they cost you future business. One major vendor failure can destroy years of trust-building with key clients.

The hidden costs are often the worst. Staff overtime to manage the crisis, legal fees for contract disputes, regulatory fines for compliance violations, and the opportunity cost of deals you couldn’t pursue while firefighting. Most companies underestimate these costs until they’re drowning in them.

Understanding these costs is the first step. Now let’s look at how to spot problems before they blow up your operations.

Red Flags: How to Spot Risky Vendors Before They Hurt You

Watch for these warning signs that spell trouble ahead:

- Financial Warning Signs

They’re asking for payment terms they never needed before. Maybe they want money upfront or keep pushing for faster payments. Their invoices start coming from different addresses, or they suddenly can’t provide financial statements. These aren’t just administrative hiccups – they’re distress signals.

- Operational Capacity Issues

Deliveries start running late more often. They blame weather, traffic, or equipment problems, but the excuses keep coming. Their warehouse looks chaotic when you visit, or they’re constantly hiring new staff. When operations get sloppy, bigger failures usually follow.

- Communication Breakdowns

Your main contact stops returning calls promptly. Emails get vague responses or take days to get answered. Key people start leaving, and nobody seems to know what’s happening with your account. Good vendors communicate clearly – struggling ones go quiet.

- Quality Control Problems

Defect rates creep up. Customer complaints increase. They start cutting corners on packaging or inspection processes. Quality problems rarely happen in isolation – they signal that internal systems are breaking down.

These red flags give you advance warning. But spotting problems is only half the battle – you need systems to protect yourself.

- Data Security Vulnerabilities

When vendors get sloppy with cybersecurity, your business pays the price. Buckley Firm found that 49% of companies suffered confidential data breaches caused by their vendors. Look for vendors who can’t provide current security certifications, have outdated systems, or seem casual about data protection protocols.

Building Your Vendor Risk Management Defense System

Here’s how to build bulletproof protection against vendor disasters:

Setting Up Monitoring Checkpoints

Set up quarterly business reviews with critical suppliers. During these meetings, discuss their capacity, upcoming challenges, and any changes in their operations. Ask about their other major clients – if they’re losing big accounts, you need to know why.

Also monitor external signals like industry news, regulatory changes, or economic conditions that could affect their business.

Establishing Backup Supplier Networks

Never put all your eggs in one basket. Maintain active relationships with at least two backup suppliers for every critical service. This doesn’t mean giving them regular business, but it does mean staying in touch.

Send them occasional RFQs, meet with their sales teams, and keep your paperwork current. When your main vendor fails, you want to make one phone call, not spend weeks finding alternatives.

Contract Clauses That Protect You

Your contracts should include performance guarantees with real penalties. Require minimum insurance coverage and make them notify you if policies lapse. Include termination clauses that let you exit quickly for cause. Most importantly, add right-to-audit clauses so you can inspect their operations when needed. These contract terms won’t prevent vendor failures, but they’ll give you legal protection when things go wrong.

Building these defenses takes time, but it’s worth it when disaster strikes. And disasters will strike – here’s how to handle them.

When Vendors Go Wrong: Response and Recovery

When vendor failures hit, your response determines how much damage you take:

- Damage assessment first – Figure out which customers are affected and what deliveries are at risk. Don’t try to fix everything at once. Focus on the most critical issues that could cost you major customers or violate important contracts.

- Activate backup plans immediately – Call your backup suppliers right away, even if their prices are higher. Getting operations moving again is worth the premium. Speed matters more than cost when you’re in crisis mode.

- Notify your insurance company – If the vendor failure causes financial losses, file claims quickly. Business interruption insurance might cover some costs, but you need to report incidents promptly to avoid claim denials.

- Communicate honestly with customers – Tell them about problems before they discover them. Explain what went wrong and what you’re doing to fix it. Customers forgive problems they can’t control, but they don’t forgive being blindsided.

- Update your risk assessments – Once things stabilize, review what warning signs you missed. Update your vendor risk management criteria based on this failure. The patterns that caught you off guard once will catch you again if you don’t learn from them.

Every vendor failure is an expensive education. The solution is learning from these disasters so they don’t happen again – and that’s where a solid vendor risk management program pays for itself.

Conclusion

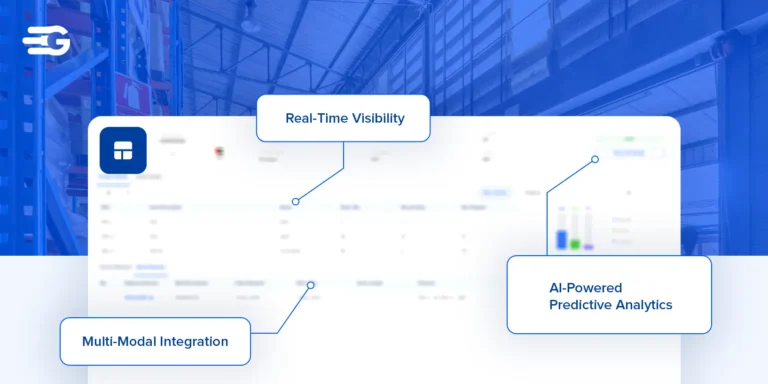

Most logistics companies handle vendor risk management backwards – they wait for problems to happen, then scramble to fix them. The smart move is flipping that approach. Map out your supplier network first, figure out who could hurt you most, then build your safety nets before you need them.

To know more about how technology can help you with vendor management, book a demo with GoComet today!