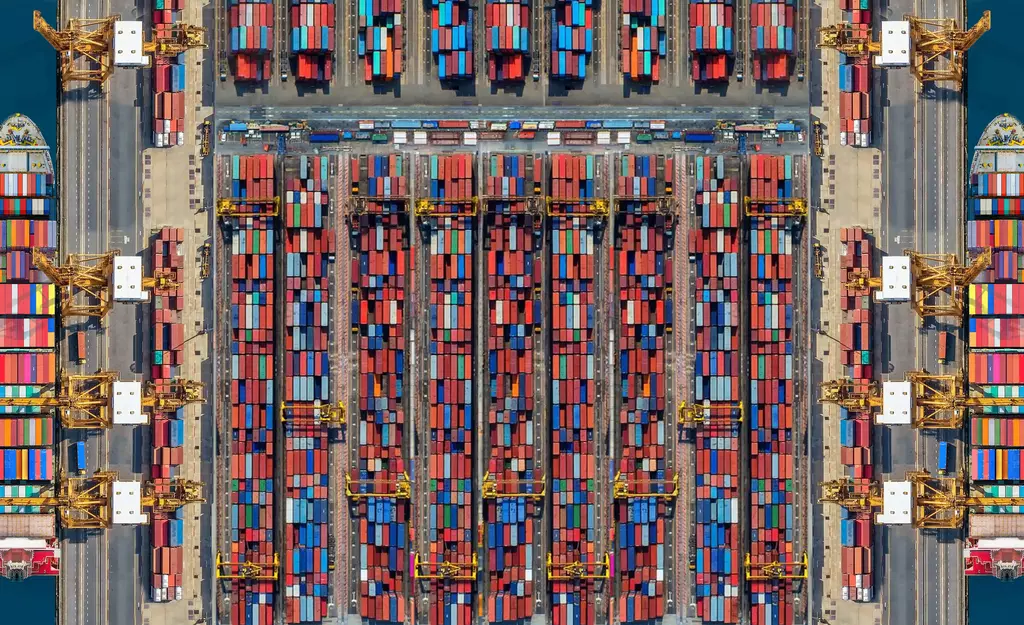

Container Empty Return Tracking: How To Track in 2024?

Container Empty Return Tracking is a critical aspect of supply chain management that enables businesses to monitor and manage the movement of containers that are not in use. Understanding the importance of global empty container tracking in your operations can significantly impact the efficiency and cost-effectiveness, especially in terms of cargo management.

One of the main benefits of empty container tracking, please understand, is improved inventory management on a global scale. By keeping track of empty container return at specific terminals, businesses can ensure they have the right number of containers available when needed, helping to avoid delays and extra costs associated with container shortage.

Empty container tracking also permits businesses to identify and address any issues related to container utilization along certain routes. By monitoring the container number and how long containers remain idle on a ship or at a return location, businesses can identify opportunities to optimize their containers’ usage and potentially reduce costs.

Furthermore, please note that empty container tracking can assist global businesses in reducing the risk of inventory shrinkage or loss. By knowing the exact return location and status of their containers, businesses can better secure their assets against theft or unauthorized use.

In addition to these benefits, empty container tracking can also contribute to global supply chain visibility and efficiency within specific regions. By having real-time data on the lines like MSC shipping line, including the whereabouts and condition of containers at different terminals, companies can make more informed decisions and streamline operations.

By implementing effective container number tracking systems at each terminal, carriers can improve their global inventory management, reduce costs, enhance cargo security, and boost overall operational efficiency. This ultimately translates to better customer notifications, improved service, and a stronger competitive advantage for the MSC shipping line in the global market.

What is Container Empty Return Tracking and Why Does It Matter?

The Significance of Empty Container Management

Empty container management plays a vital role in optimizing resource utilization within the supply chain of a particular region. By effectively tracking the route and location of empty containers at different terminals, businesses can minimize unnecessary storage costs and streamline their operations on a global scale.

Here are some ways in which empty container management can help optimize resource utilization:

1. Reduce storage costs: By accurately tracking the movement of empty containers, businesses can avoid overstocking and unnecessary storage expenses. This can lead to significant cost savings and improved overall efficiency.

2. Improve inventory control: Effective empty container management allows businesses to better monitor inventory levels and ensure that containers are available when and where they are needed along the decided route. This can prevent shortages and delays in the supply chain.

3. Streamline operations: A well-managed empty container system can help streamline logistics and transportation processes. This can lead to improved productivity, reduced lead times, and better overall performance.

4. Minimize waste: By efficiently managing empty containers, businesses can minimize waste and reduce the environmental impact of their operations. This can contribute to a more sustainable supply chain.

5. Enhance customer satisfaction: Accurate empty container management can help ensure that products are delivered on time and in good condition, leading to higher customer satisfaction and loyalty.

Overall, effective empty container management is essential for optimizing resource utilization and improving the efficiency of the supply chain. By implementing robust tracking and monitoring systems, businesses can better control their inventory, reduce costs, and enhance overall performance.

Challenges Faced Due to Inefficient Empty Container Tracking

Inefficient empty container tracking can lead to operational challenges such as container shortages, increased demurrage charges, and disruptions in the supply chain. These challenges can impact the overall efficiency and profitability of the business. Inefficient empty container tracking can result in increased demurrage charges because containers might not be returned on time, leading to additional costs for the business. This can also lead to disruptions in the supply chain, as delays in returning empty containers can cause delays in getting new shipments out. This can impact customer satisfaction and ultimately lead to loss of business.

Container shortages can also occur when empty containers are not efficiently tracked and managed. This can result in delays in receiving new containers and can hinder the flow of goods in and out of the business. This inefficiency can impact the overall efficiency of the business and result in lost revenue opportunities.

Inefficiencies in empty container tracking can also lead to increased operational costs. With containers not being returned on time and shortages occurring, businesses may have to spend more on transportation and storage of containers, further impacting their profitability.

Therefore, it is essential for businesses to implement efficient empty container tracking systems to ensure that containers are returned on time and efficiently managed. This can help to prevent container shortages, reduce demurrage charges, and ensure a smooth flow of goods in the supply chain, ultimately improving the overall efficiency and profitability of the business.

How Empty Container Tracking Can Improve Supply Chain Efficiency

Effective empty container tracking contributes to improved supply chain efficiency by ensuring timely container availability, minimizing idle time, and optimizing container utilization. Real-time tracking of empty containers allows for better planning and optimization of container movements, reducing the risk of containers being held up in one location while needed elsewhere. This ensures that containers are made available for use at the right time and place, preventing delays in the transportation process.

Additionally, by closely monitoring container movements and locations, supply chain managers can identify opportunities to streamline and optimize container utilization. For example, they can identify patterns of container demand and adjust container distribution to ensure a more balanced and efficient use of available resources.

How Does Empty Container Tracking Impact Supply Chain Management?

Understanding the Role of Empty Container Tracking in Supply Chain Visibility

Empty container tracking enhances supply chain visibility by providing real-time insights into container movements, enabling proactive decision-making and efficient resource allocation.

Demurrage and Detention Charges: The Implications of Ineffective Empty Container Tracking

Ineffective empty container tracking can result in increased demurrage and detention charges, impacting the overall cost of operations and eroding profitability.

Ensuring Container Availability with Efficient Tracking Systems

Efficient tracking systems ensure that containers are readily available when needed, minimizing disruptions in production and distribution processes.

Identifying and Resolving Bottlenecks in Container Movement through Tracking

By identifying bottlenecks in container movement, businesses can take proactive measures to streamline operations and enhance overall efficiency.

Integrating Empty Container Tracking with Inventory Management

Integrating empty container tracking with inventory management systems facilitates comprehensive control over stock levels and enhances operational transparency.

What Are the Technologies and Solutions Available for Empty Container Tracking?

RFID Technology: Revolutionizing Empty Container Tracking

RFID technology is revolutionizing empty container tracking by enabling automated identification and tracking of containers, leading to enhanced efficiency and reduced manual errors.

GPS and IoT Integration for Real-time Empty Container Monitoring

Integration of GPS and IoT technologies allows for real-time monitoring of empty containers, providing accurate location data and aiding in proactive decision-making.

Cloud-based Empty Container Tracking Platforms

Cloud-based tracking platforms offer the flexibility of accessing and managing container data from anywhere, streamlining operations and enhancing accessibility.

Software Integration with Existing Supply Chain Systems

Seamless integration of tracking software with existing supply chain systems ensures a cohesive approach to managing container movements and optimizing resource utilization.

Customization and Scalability in Empty Container Tracking Solutions

Scalable and customizable tracking solutions cater to the specific needs of businesses, allowing for efficient adaptation to evolving operational requirements.

How to Overcome Common Challenges in Implementing Empty Container Tracking Systems?

Resistance to Change: Navigating Adoption Hurdles

Overcoming resistance to change involves effective communication, collaboration, and demonstrating the tangible benefits of the new tracking systems to stakeholders.

Cost Considerations and ROI Analysis for Implementing Empty Container Tracking Systems

Conducting a thorough cost-benefit analysis and ROI assessment is essential to justify the implementation of tracking systems and ensure long-term viability.

Best Practices for Training and Onboarding Personnel on New Tracking Systems

Comprehensive training and onboarding programs are crucial for ensuring the seamless adoption and utilization of new tracking systems by personnel.

Addressing Security and Data Privacy Concerns in Empty Container Tracking

Addressing security and privacy concerns involves implementing robust data security measures and adhering to regulatory requirements to safeguard container tracking information.

Collaborating with Stakeholders for Seamless Implementation and Integration

Collaboration with stakeholders, including suppliers and logistics partners, is essential for ensuring a cohesive and integrated approach to implementing tracking systems.

What Are the Future Trends and Innovations in Empty Container Tracking?

Predictive Analytics and AI-driven Insights in Empty Container Management

Predictive analytics and AI-driven insights offer the potential to optimize container management through proactive decision-making and resource allocation.

Blockchain Integration for Traceability and Security in Container Movements

Blockchain integration ensures enhanced traceability and security in container movements, mitigating the risk of fraudulent activities and enhancing transparency.

Sustainability and Environmental Impact Considerations in Empty Container Tracking

Considering environmental impact in container tracking involves adopting sustainable practices and technologies to minimize the ecological footprint of container movements.

Automation and Robotics in Container Handling and Tracking

Automated container handling and tracking solutions leverage robotics to streamline operations and enhance the efficiency of container movements.

Industry Collaboration and Standardization Efforts for Enhanced Tracking Solutions

Industry-wide collaboration and standardization efforts contribute to the development of comprehensive and interoperable tracking solutions for the benefit of the entire supply chain ecosystem.