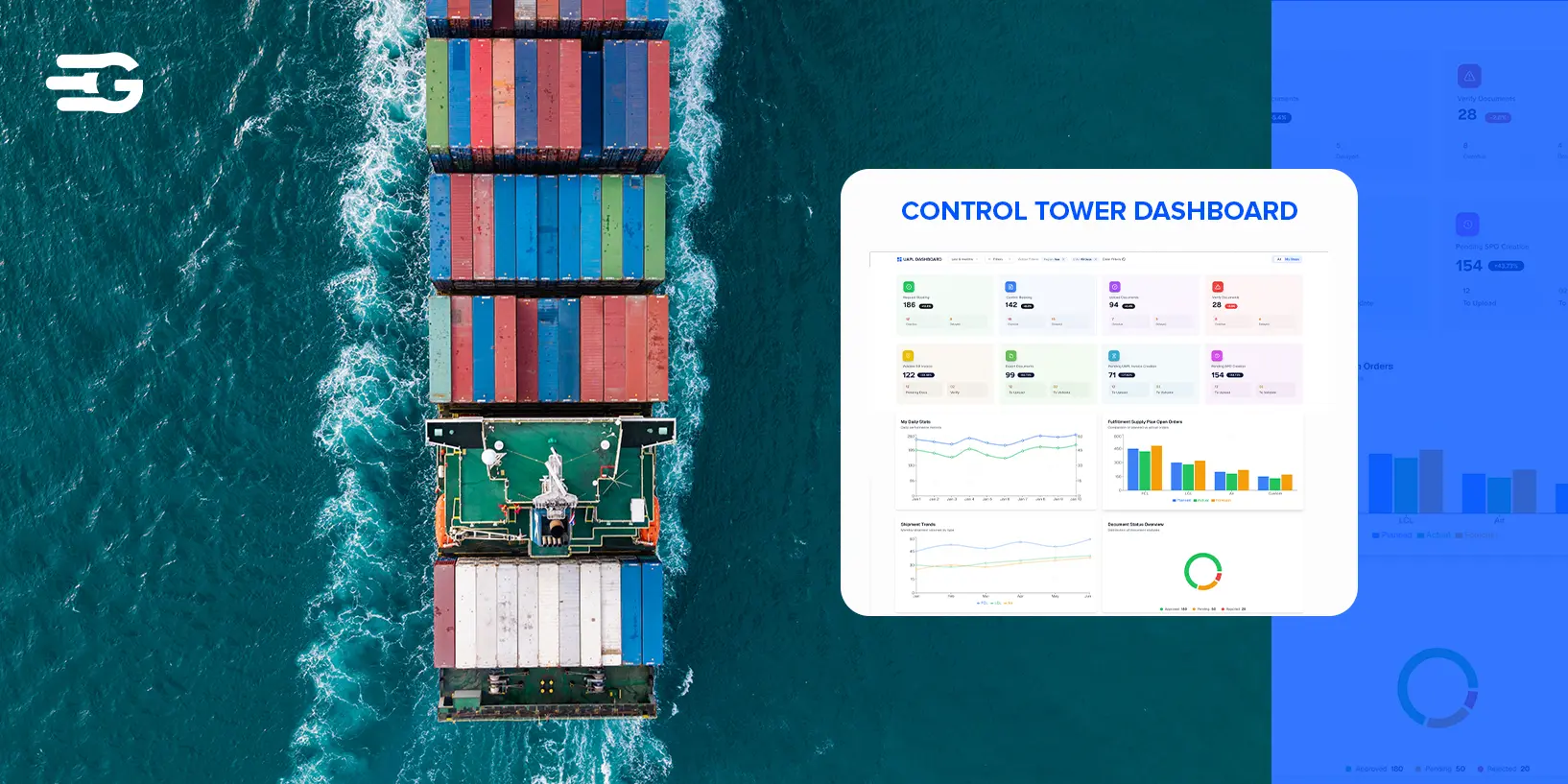

5 Supply Chain Control Tower Disasters You Must Avoid

A supply chain control tower is a centralized digital platform designed to provide end-to-end visibility across your entire supply chain network. When implemented correctly, these systems promise improved efficiency, reduced costs, and better customer satisfaction through proactive management of shipments, inventory, and supplier relationships.

However, the reality is that many supply chain control tower disasters occur when businesses rush into implementation without proper planning or realistic expectations. These supply chain control tower disasters don’t just waste money, they can actually make your operations worse than before. Let’s read about five critical mistakes you can avoid.

What Makes Control Tower Implementations Go Wrong

Supply chain control tower disasters typically stem from a combination of technical missteps and organizational oversights. Many companies get excited about the promise of complete visibility and rush into selecting platforms without thorough evaluation of their existing systems and integration requirements.

This leads to compatibility issues, data silos, and fragmented information that defeats the entire purpose of centralized monitoring. The human element creates even bigger problems. Teams often resist new technology when they haven’t been properly trained or consulted during the selection process.

Without adequate change management, employees continue using old methods while the expensive new control tower sits underutilized.

5 Control Tower Disasters You Can Avoid

These supply chain control tower disasters are preventable, but they require careful planning, realistic timelines, and commitment from leadership to address both technical and cultural challenges before they derail your investment.

Disaster 1: Choosing the Wrong Platform Without Proper Integration Testing

One of the most devastating supply chain control tower disasters happens when companies select flashy platforms based on marketing presentations rather than technical compatibility.

The root problem lies in skipping integration testing during the evaluation phase. Companies often focus on feature lists and user interfaces while ignoring whether the platform can actually connect to their warehouse management systems, transportation management software, and supplier portals.

When integration fails, you end up with manual data entry, delayed updates, and incomplete visibility that makes decision making even harder than before. The solution is simple but often overlooked: conduct thorough integration testing with real data from your actual systems before signing any contracts, not after deployment begins.

Disaster 2: Rolling Out Too Fast Without Team Training

Supply chain control tower disasters frequently occur when organizations rush implementation without proper team preparation. Here’s what a realistic rollout timeline should include:

- Weeks 1-2: Platform orientation sessions for key users

- Weeks 3-4: Hands-on training with actual company data scenarios

- Weeks 5-6: Pilot testing with small team groups

- Weeks 7-8: Feedback collection and system adjustments

- Weeks 9-10: Gradual rollout to additional departments

- Weeks 11-12: Full deployment with ongoing support available

Without such a structured approach, teams abandon new systems and revert to familiar manual processes. The control tower becomes an expensive dashboard that nobody uses effectively.

Disaster 3: Ignoring Data Quality Before Implementation

Supply chain control tower disasters often start with a fundamental oversight: assuming your existing data is clean enough to power a new visibility platform.

Poor data quality creates cascading problems that make control towers counterproductive. When supplier codes don’t match between systems, location data contains typos, or product information is outdated, your control tower displays conflicting information that teams can’t trust. Decision makers lose confidence in the system and return to manual tracking methods, defeating the investment entirely.

The most common data quality issues include:

- Duplicate records

- Missing fields

- Inconsistent naming conventions

- Outdated reference information

These problems multiply when multiple data sources feed into your control tower without proper cleansing.

Smart companies audit their data quality months before implementation, establishing cleaning protocols and validation rules. This prevents supply chain control tower disasters and ensures your investment delivers accurate, actionable insights from day one.

Disaster 4: Not Getting Buy-in From All Stakeholders

Supply chain control tower disasters frequently result from incomplete stakeholder engagement during the planning phase.

When key departments feel excluded from the selection and design process, they resist adoption and continue using separate systems that undermine centralized visibility.

| Stakeholder Group | Common Concerns | Buy-in Strategy |

| Operations Teams | Fear of job redundancy | Show how automation handles routine tasks, freeing time for strategic work |

| IT Department | Integration complexity | Involve in technical evaluation and provide adequate implementation resources |

| Finance Teams | ROI uncertainty | Present clear cost-benefit analysis with measurable KPIs |

| Procurement | Process changes | Demonstrate improved supplier performance tracking capabilities |

| Customer Service | Learning curve | Highlight faster response times and better customer communication tools |

Without proper stakeholder alignment, supply chain control tower disasters manifest as parallel systems, data silos, and user resistance.

Each department continues their established workflows while the control tower operates in isolation. Success requires addressing specific concerns early, involving stakeholders in platform selection, and clearly communicating benefits relevant to each group’s daily responsibilities.

Disaster 5: Underestimating Change Management Requirements

Supply chain control tower disasters commonly stem from treating implementation as purely a technical project while ignoring the massive organizational changes required. Companies focus on software installation and data migration but forget that success depends on people changing how they work daily.

Effective change management requires multiple components:

- Performance metrics alignment: Updating KPIs to reflect control tower capabilities and expectations

- Leadership commitment: Executives must actively champion the new system and address resistance quickly

- Communication strategy: Regular updates explaining benefits, timeline, and addressing concerns from all levels

- Role redefinition: Clear documentation of how job responsibilities change with the new system

- Support structure: Dedicated help desk and super-users available during transition period

- Feedback loops: Regular check-ins to identify adoption challenges and system improvements needed

Without structured change management, employees find workarounds, maintain shadow systems, and resist new processes.

The control tower becomes an expensive monitoring tool rather than an operational table-turner that improves decision making and efficiency across the entire supply chain network.

How GoComet Prevents These Failures

GoComet’s approach directly addresses the root causes of supply chain control tower disasters through practical, proven solutions.

Rather than promising everything and delivering complexity, GoComet focuses on real-world logistics needs with tools that actually work from day one.

| Common Disaster | GoComet Solution | Key Benefits |

| Wrong Platform Selection | Modular API-first architecture with pre-built integrations for major carriers, ports, and ERP systems | Seamless connection to existing systems without costly customization |

| Rushed Implementation | Phased rollout with dedicated customer success team and hands-on training programs | 90%+ user adoption rates with structured onboarding process |

| Poor Data Quality | Multi-source data validation with automated cleansing and real-time verification from carrier APIs | Clean, accurate shipment data that teams can trust for decision making |

| Missing Stakeholder Buy-in | Role-based dashboards and customizable alerts tailored to each department’s specific needs | Finance sees cost savings, operations gets delay alerts, customers receive proactive updates |

| Inadequate Change Management | Intuitive interface requiring minimal training plus ongoing support and system optimization | Teams start seeing value within weeks, not months |

GoComet prevents supply chain control tower disasters by delivering measurable ROI through freight cost savings and reduced disruption impact.

The platform provides actionable insights that enable proactive responses to delays, incidents, and exceptions rather than just monitoring problems after they occur.

Conclusion

Supply chain control tower disasters are expensive lessons that smart companies can avoid by learning from others’ mistakes. The key lies in choosing platforms that prioritize integration testing, proper training, data quality, and stakeholder alignment over flashy features. GoComet’s modular approach addresses these critical success factors while delivering measurable results through real-time visibility and actionable insights.

Book a demo with GoComet today to build a resilient visibility framework without the common pitfalls.