What Is The Bullwhip Effect In Supply Chain? Causes & Solutions

Ever notice how a tiny bump in sales can somehow turn into your supplier freaking out and ramping up production like crazy? Welcome to the bullwhip effect in supply chain – it’s basically when small demand changes get blown way out of proportion as they travel backward through your supply network.

Here’s what happens: your customer orders 10% more widgets, so you order 15% more from your distributor to be safe. They do the same thing to their supplier, who does it to the manufacturer. Before you know it, everyone’s sitting on mountains of inventory they don’t need, or scrambling to catch up when demand actually drops.

Read on to find out why this mess keeps happening and how to fix it.

What Causes The Bullwhip Effect In Supply Chain

The bullwhip effect happens because of a few key problems that stack on top of each other. Most of it comes down to people making decisions with incomplete information and trying to play it safe.

- Demand Forecasting Errors Nobody can predict the future perfectly, but when your sales team thinks demand will jump 20% and orders accordingly, that signal gets amplified at every level. Your distributor sees your big order and thinks there’s a trend, so they order even more. The bullwhip effect in supply chain gets worse because each person in the chain adds their own “just in case” buffer.

- Order Batching Instead of ordering small amounts regularly, most companies batch their orders to save on shipping and processing costs. This creates artificial spikes in demand that look like real market changes. When everyone does this at different times, it creates a rollercoaster of orders that has nothing to do with actual customer demand.

- Price Fluctuations and Promotions Sales and discounts mess with normal ordering patterns. When you offer a 15% discount, customers stock up, creating a temporary spike followed by a valley. Suppliers see this pattern and think demand is more volatile than it really is, leading to the bullwhip effect in supply chain.

- Shortage Gaming When products are scarce, buyers often inflate their orders hoping to get at least some of what they need. Suppliers see these inflated orders and think demand is higher than reality. Once supply catches up, orders drop dramatically, creating the classic bullwhip pattern that damages the entire supply chain.

To understand it more clearly, let’s see some examples now.

Examples Of The Bullwhip Effect In Supply Chain

Think about what happened with toilet paper during the pandemic. People bought slightly more than usual because they were staying home, but stores saw empty shelves and assumed demand had skyrocketed. They placed huge orders with distributors, who then told manufacturers there was a massive shortage.

The bullwhip effect in supply chain meant manufacturers thought they needed to triple production when customers were only buying a bit more than normal.

The same thing happens with seasonal products all the time. A retailer sees winter coats selling well in October and orders heavily for November. Their supplier notices the big order and assumes it’s going to be a harsh winter, so they ramp up production and order more materials.

By the time everyone realizes it was just normal seasonal demand, warehouses are stuffed with coats nobody wants, and spring inventory orders get slashed to compensate.

The True Cost Of The Bullwhip Effect In Supply Chain

The effect hits your wallet in ways that add up fast, and most business owners don’t realize how much it’s actually costing them.

- Inventory Carrying Costs – Every extra unit sitting in your warehouse costs money for storage space, insurance, taxes, and the risk it becomes obsolete before you sell it.

- Emergency Shipping and Expediting – When you’re caught short because of bad forecasting, you end up paying premium rates for rush orders and air freight instead of normal ground shipping

- Production Inefficiencies – Constantly changing production schedules means more setup time, overtime wages, and equipment that’s not running at optimal capacity

- Lost Sales and Customer Relationships – Stockouts don’t just mean missed revenue; they send customers to competitors who might keep them permanently

- Working Capital Problems – Money tied up in slow-moving inventory can’t be used for growth opportunities or dealing with unexpected expenses

- Supplier Relationship Strain – Erratic ordering patterns make it harder to negotiate good terms and can damage partnerships you’ve spent years building

The frustrating part is that these costs often don’t show up as a single line item on your P&L, so it’s easy to miss how much the bullwhip effect in supply chain is really costing your business.

How To Reduce The Bullwhip Effect In Supply Chain

Reducing the bullwhip effect means fixing the information and decision-making problems that create it in the first place. Here are some steps you can take.

- Stop Guessing What Customers Want

Use actual sales data from your point-of-sale systems instead of relying on order history or gut feelings. Share this real demand information with your suppliers so they’re not making decisions based on your inflated safety orders.

- Make Your Supply Chain Talk To Each Other

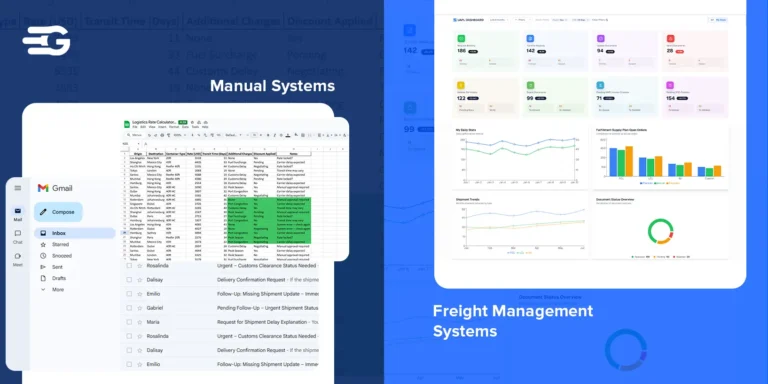

Break down the walls between you and your suppliers by sharing inventory levels, upcoming promotions, and market insights. You can use supply chain collaboration platforms like GoComet for this. When everyone has the same information, there’s less reason to add safety buffers that create the effect.

- Order More Often, Not More Units

Instead of placing huge orders once a month, try smaller orders every week. This smooths out demand signals and gives you better flexibility to adjust when things change.

- Keep Pricing Steady

Constant sales and promotions mess with normal buying patterns. Try to minimize price changes and when you do run promotions, tell your suppliers it’s temporary so they don’t mistake the spike for permanent growth.

- Build Real Partnerships With Key Suppliers

Move beyond just sending purchase orders to having regular planning meetings where you discuss forecasts, capacity, and market trends together. The better your suppliers understand your business, the less likely they are to overreact to order changes.

Using GoComet To Control The Bullwhip Effect In Supply Chain

Technology can help reduce the effect, but only if you choose tools that actually solve the information and communication problems causing it.

That’s where GoComet comes in. It alone serves as:

- Integrated Planning System – Connects your sales forecasting with inventory planning and supplier communications so everyone works from the same numbers

- Real-Time Visibility Platform – Lets you and your suppliers see what’s actually happening with inventory levels and demand patterns instead of waiting for monthly reports

- Supplier Communication Portal – Direct channels for sharing forecasts, inventory levels, and market intelligence without playing telephone through multiple departments

The key is making sure whatever technology you choose actually improves communication and information sharing rather than just digitizing your existing broken processes.

Good technology should make the bullwhip effect more visible so you can fix it, not hide it behind fancy dashboards.

Next Steps

The bullwhip effect in supply chain management is one of those problems that seems complicated but comes down to basic communication breakdowns.

The next step is getting visibility into where this is happening in your own operations. Start by mapping out your key suppliers and understanding how information flows between you. Look at your ordering patterns over the past year. This way, you’ll probably spot the telltale signs of demand amplification pretty quickly.

If you want to see how technology can help streamline this process, GoComet offers supply chain visibility tools worth exploring.