Top 12 Supply Chain Planning Software in 2025

Supply chains are unpredictable with fluctuating demand, delays, and inventory changes create challenges. Supply chain planning software keeps operations smooth and under control.

As Johny Stephen, a speaker at Odyssey Singapore, put it: “Every sip of coffee represents the efforts of over 200 individuals involved in its journey, highlighting the sheer complexity and scale of the supply chain.” That’s the reality of modern supply chains. Thousands of moving parts, endless coordination, and zero room for error. Without the right tools, things go downhill fast.

That’s where supply chain planning software steps in. The best ones streamline operations, cut costs, and keep everything running smoothly. But with so many options out there, which one actually delivers?

We’ve done the digging. Here are the top 12 supply chain planning solutions for 2025, so you can pick the right fit and stay in control. Let’s get into it.

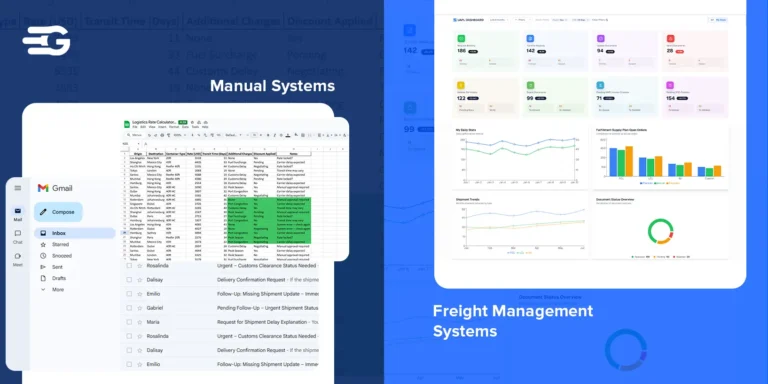

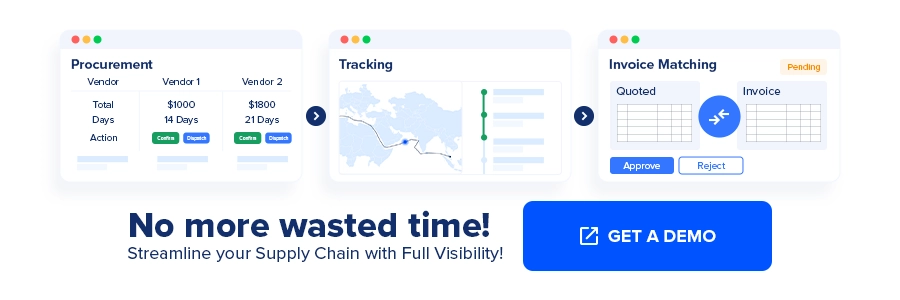

1. GoComet

GoComet takes the guesswork out of supply chain planning with AI-powered visibility and automation. Keeping track of shipments across ocean, air, road, and rail? Done. Struggling with freight rates? GoComet automates procurement, ensuring you get the best possible deal without endless negotiations. With dynamic route optimization, businesses can adjust shipping routes in real time, cutting costs and improving efficiency.

Accoridng to the CEO of GoComet, Gautam Prem Jain “GoComet has integrated 293 ocean carriers into its system, creating the largest network of ocean freight carriers for better cost and efficiency management.” That means fewer delays, smarter vendor selection, and automated RFQ management, eliminating the back-and-forth of manual negotiations.

But it’s not just about tracking shipments. Comprehensive supply chain analytics give businesses deeper insights into logistics performance, helping them make data-backed decisions. Predictive analytics provide real-time ETAs and disruption alerts, keeping operations running smoothly. While GoComet excels in automation and cost optimization, it may have limited SKU-level visibility, making it challenging for businesses to track individual product performance at a granular level.

That’s why global enterprises like Unilever and Honda rely on GoComet to reduce costs, optimize routes, and boost efficiency. If you want a smarter, stress-free way to manage your supply chain, GoComet delivers.

Ratings (as of May, 2025):

- G2: 4.8/5

- Capterra: 4.8/5

Customer Testimonial:

How GoComet Helped Transform This Global Brand’s Supply Chain

2. SAP

SAP Supply Chain Planning Software isn’t just another planning tool. it’s a powerhouse for enterprises needing precision, scalability, and real-time coordination. With AI-driven demand forecasting, businesses can predict shifts in supply and demand, adjusting strategies before disruptions occur. Its multi-echelon inventory optimization ensures companies maintain the right stock levels, balancing profitability while keeping buffer stock for unexpected demand.

What truly sets SAP apart is its deep ERP integration. Instead of dealing with disconnected systems, businesses get a unified, intelligent platform where data flows effortlessly across procurement, logistics, and financial planning. That means synchronized decision-making, eliminating blind spots, and making real-time collaboration possible. But SAP’s advanced supply chain analytics do more than just improve visibility; they provide actionable insights that enhance risk management and streamline planning.

However, this level of sophistication comes with challenges. SAP’s complexity and steep learning curve mean it requires advanced technical expertise, and onboarding can be tough due to differences in data structures. Integration with legacy systems like SAP ECC can also be tricky, as initial data formatting needs fine-tuning for seamless operation.

For global enterprises managing intricate distribution networks, SAP offers the automation, predictive insights, and flexibility needed to cut costs, optimize resources, and stay ahead of market fluctuations.

Ratings (as of May, 2025):

- G2: 4.3/5

- Gartner: 4.3/5

Testimonials:

“Consultant team very difficult to work with, not open to share information or offer improvements. Design team (internal to SAP) has been responsive and helpful.”

3. Logility

Logility takes the uncertainty out of supply chain planning with AI-driven forecasting and automation. Instead of relying on outdated methods, its machine learning models analyze demand patterns to predict inventory needs, minimize waste, and prevent stockouts. But demand planning isn’t just about forecasting; it’s about precision. Multi-echelon inventory tools help businesses set optimal stock levels, reducing costs while balancing service levels to avoid excess or shortages.

Planning in a fast-moving market? Logility keeps businesses agile with scenario planning and analytics, allowing them to simulate supply chain disruptions, assess risks, and make data-backed decisions before issues arise. Real-time collaboration tools ensure teams stay aligned, sharing insights instantly across departments for smoother execution. However, with this level of sophistication comes a learning curve, advanced AI analytics and scenario planning require training, making onboarding more challenging for teams unfamiliar with the platform.

For companies dealing with large-scale operations, Logility’s powerful automation shines, but integrating with existing systems and processing massive data sets can slow down real-time planning in complex networks. Still, for businesses looking to streamline operations, cut costs, and stay one step ahead of demand fluctuations, Logility delivers a smart, adaptable supply chain solution that keeps things running smoothly, even in unpredictable markets.

Ratings (as of May, 2025):

- G2: 4.1/5

- Gartner: 4.6/5

Testimonials:

“Had some functionality that was rated out of scope after we were too far into the project to go another direction. Had several SOWs to pay after initial negotiations. But delivered on time.”

4. Coupa

Coupa makes cost efficiency the backbone of supply chain planning. It helps businesses control spending, streamline procurement, and manage suppliers with ease. AI-driven cost optimization uncovers hidden savings, ensuring every dollar spent adds real value. Real-time tracking helps companies negotiate better contracts and prevent overspending.

Need a smarter approach to logistics? Network and location optimization refine warehouse placement and transportation routes for better efficiency. Digital twin technology models different supply chain scenarios for smarter planning. However, these advanced features come with a learning curve, especially for new users.

Beyond cost savings, Coupa integrates sustainability and risk analysis into supply chain decisions. It evaluates climate impact while optimizing for cost and carbon reduction. Customer support has reportedly declined post-acquisition, making issue resolution slower. Some features, like cXML invoicing and catalog management, need improvement.

Ratings (as of May, 2025):

- G2: 4.2/5

- Gartner: 4.7/5

Testimonials:

“Ease of communication amongst multiple different customers. Lack of ability to communicate with all other software working in.”

5. E2Open

E2Open connects over 480,000 manufacturers, distributors, and logistics providers on a single platform. Suppliers, manufacturers, and logistics teams collaborate seamlessly, reducing miscommunication. Predictive ETAs and real-time tracking keep shipments on schedule across all transportation modes. Automated workflows cut manual tasks, making supply chain management easier.

Worried about disruptions? E2Open’s AI-driven analytics spot risks early, helping businesses adjust before delays happen. Teams across procurement, production, and delivery stay aligned with built-in collaboration tools. However, new users may face a learning curve, as mastering its extensive features takes time.

E2Open also simplifies shipment management, consolidating bookings into one platform. Businesses can compare carrier invoices to lower logistics costs and streamline contracts. However integrating E2Open with legacy systems can be complex, causing potential workflow delays.

Ratings (as of May, 2025):

- G2: 4.1/5

- Gartner: 4.3/5

Testimonials:

“A system that can manage all your rates, carrier, and spend all in 1 system. System doesn’t incorporate ocean freight and air shipment. it’s only on the road truck or rail carriers.”

6. Anaplan

Anaplan makes supply chain planning flexible; no rigid models, and no outdated forecasts. Its cloud-based platform ensures strategies adapt in real time, backed by the latest data. Need to test different scenarios? Anaplan’s intelligent modeling predicts outcomes, optimizes inventory, and fine-tunes logistics without the guesswork.

With AI-powered forecasting, businesses stay ahead of demand shifts and respond to disruptions before they escalate. Customizable dashboards provide clear insights, helping teams make data-driven decisions. However new users may face a steep learning curve due to Anaplan’s vast feature set.

For enterprises handling complex supply networks, Anaplan delivers agility, precision, and real-time control. It integrates finance, supply chain, and operations, ensuring seamless collaboration. However, its pricing may be too high for smaller businesses with limited budgets.

Ratings (as of May, 2025):

- G2: 4.6/5

- Capterra: 4.5/5

Testimonials:

“The platform is very good but we do not receive the support we need or it takes time for them to respond to our concerns. Also, when we requested for model performance analysis, the analysis provided to us was at surface-level or things that we already know how to fix. ”

7. Blue Ridge Global

Blue Ridge simplifies inventory planning with machine learning-powered demand forecasting, reducing stockouts and excess inventory. Its automated inventory optimization ensures stock levels always match demand, helping businesses avoid costly miscalculations.

With advanced analytics, companies get clear supply chain insights for smarter, data-driven decisions. Seamless ERP integration keeps operations running smoothly by syncing data across systems. However, forecasting depends heavily on historical data, which may not be ideal for fast-changing markets.

While Blue Ridge delivers precision in inventory planning, implementation can take time, delaying its full benefits. But once up and running, it provides efficient, accurate supply chain management without the guesswork.

Ratings (as of May, 2025):

- G2: 4.7/5

- Capterra: 4.9/5

Testimonials:

“Blue Ridge has brought our purchasing department to the next level. Lowered inventory levels, lowered carrying costs, increased fill rates and increased inventory turns. Customer support (Lifeline) is a huge plus, they are always very responsive to our needs. Some newly introduced features may be buggy, but nothing major.”

8. Board

Board blends supply chain planning with business intelligence, turning raw data into clear, actionable insights. It goes beyond basic forecasting, offering advanced analytics, budgeting tools, and strategic planning in one place.

With predictive modeling and automated reporting, businesses can anticipate demand shifts, optimize inventory, and streamline procurement; all while staying agile and cost-effective. Multi-functional planning capabilities bring strategy, finance, and supply chain together for a unified decision-making process.

Customizable dashboards and centralized data analytics ensure the right KPIs are always in view, improving cross-team collaboration. However, the setup is complex, requiring external support, and calculation visibility is limited, making it harder to track formulas. But once mastered, Board delivers seamless, data-driven planning without the guesswork.

Ratings (as of May, 2025):

- G2: 4.4/5

- Capterra: 4.5/5

Testimonials:

“The tool itself has been great – implementation had its hiccups as they outsourced us to outside consultants and we had to start from scratch on scoping.”

9. Solvoyo

Solvoyo makes supply chain planning effortless with its AI-driven, fully automated platform. No more manual number-crunching or reactive decisions, real-time analytics spot inefficiencies and suggest the smartest next move.

Need to adjust inventory, reroute shipments, or forecast demand on the fly? Solvoyo automates it all, ensuring faster decisions, lower costs, and fewer disruptions. With end-to-end supply chain visibility, businesses can make proactive adjustments instead of constantly firefighting.

However, integration with ERP systems can be complex, requiring technical expertise. The user interface isn’t the most intuitive, so some training may be needed. But once set up, Solvoyo delivers full automation, intelligence, and speed; all in one seamless platform.

Ratings (as of May, 2025):

- G2: 4.5/5

- Capterra: 4.6/5

Testimonials:

“Solvoyo has transformed our supply chain with its automated processes and real-time analytics, giving us better visibility and control over our operations.”

10. StockIQ

StockIQ simplifies inventory and demand planning, helping distributors and manufacturers keep stock levels just right. No more cash tied up in excess inventory or lost sales from stockouts; its AI-driven forecasts ensure perfect balance.

Beyond forecasting, StockIQ tracks supplier performance, lead times, and seasonal trends, helping businesses stay ahead of fluctuations. Automation and real-time insights cut carrying costs and eliminate manual guesswork, keeping operations efficient.

However, StockIQ may not scale well for large enterprises needing advanced features. Its accuracy depends on high-quality data, making precise inputs crucial. But for small to mid-sized businesses, StockIQ delivers precision, automation, and cost savings; all in one smart package.

Ratings (as of May, 2025):

- G2: 4.6/5

- Capterra: 4.7/5

Testimonials:

“SIQ is easy to learn and intuitive to use. Their development team makes smart software updates and seek user feedback to make the experience and tools more functional and under-friendly. It would be nice if there is an icon or marker showing if a product has a model adjustment on a forecast that might affect normal SIQ algorithms. It’s difficult to see these are in effect when managing many SKUs.”

11. O9 Solutions

O9 Solutions goes beyond supply chain planning; it delivers real-time intelligence to keep businesses ahead of disruptions. With AI-driven forecasting, scenario modeling, and predictive analytics, companies can anticipate market shifts, supplier delays, and demand spikes before they cause problems.

The platform connects demand, supply, and financial planning into a single view, ensuring all departments stay aligned. Need to test different scenarios instantly? O9’s real-time modeling shows the impact of every decision, helping businesses adapt fast.

However, implementing O9 can be complex, given its broad range of integrations and features. But for companies looking to optimize operations, reduce risks, and improve agility, O9 Solutions delivers fast, data-driven planning at scale.

Ratings (as of May, 2025):

- G2: 4.6/5

- Capterra: 4.8/5

Testimonials:

“With O9 Solutions, we’ve improved our planning accuracy significantly, and the scenario modeling feature has been a game-changer for quick decision-making.”

12. Arkieva

Arkieva puts businesses in full control of demand planning, inventory optimization, and S&OP. With AI-driven tools, companies can cut lead times, reduce disruptions, and fine-tune production schedules for smoother operations.

Need to forecast demand accurately and balance stock levels? Arkieva identifies bottlenecks, enhances supplier collaboration, and prevents overstocking, keeping supply chains cost-efficient. While its reporting features may be limited and the interface less modern, Arkieva still delivers strong automation and predictive insights for smarter planning.

For businesses seeking real-time intelligence and seamless operations, Arkieva offers flexible workflows, scenario planning, and end-to-end control.

Ratings (as of May, 2025):

- G2: 4.4/5

- Capterra: 4.6/5

Testimonials:

“Good for Demand planning and forecasting. Integration capabilities need to evolve and support system has to improved”

Conclusion

Selecting the best supply chain planning software can streamline operations, reduce costs, and improve customer satisfaction. Each of the software options reviewed here provides unique features, so consider what matters most to your business to find the best fit.

FAQs

What is Supply Chain Planning Software?

Supply chain planning software helps businesses optimize inventory, forecast demand, and coordinate logistics using AI and automation. It reduces costs, prevents stock issues, and improves efficiency by enabling real-time, data-driven decisions.

What Features Should a Supply Chain Planning Solution Have?

A good solution should offer:

- Real-Time Visibility – Instant updates for quick decision-making.

- AI-Powered Forecasting – Prevent stock shortages or overstocking.

- Inventory Optimization – Maintain balanced stock levels.

- Scalability – Grow with your business needs.

- Seamless Integration – Connect with ERP, CRM, and other systems.

- Scenario Planning – Prepare for market changes.

- Cost Management – Optimize logistics and procurement.

These features help businesses cut costs, improve efficiency, and stay competitive.