What is Supply Chain Optimization? Key Benefits & Best Practices

Supply chain optimization is all about improving how your supply chain works, from start to finish. Think of it as fine-tuning the gears in a machine; getting each part to work better, faster, and more efficiently. Whether it’s streamlining operations, cutting costs, or enhancing service delivery, optimizing supply chain processes is all about finding smarter ways to make things run smoothly.

In simpler terms, it means aligning the right resources at the right time, ensuring minimal waste, and meeting customer demands with precision. Supply chain optimization tools help businesses achieve better supply chain visibility by offering real-time data that can guide decisions.

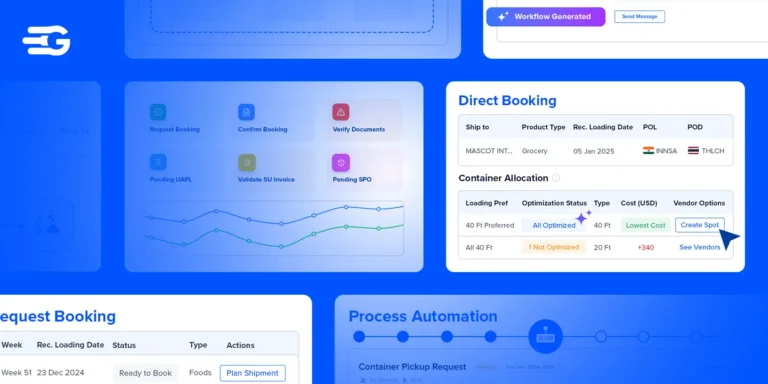

It’s not just about reducing costs; it’s about making informed decisions that improve overall supply chain performance. When companies leverage technology, they can automate their supply chain to gain better control over logistics and reduce human error. Supply chain automation tools, for example, can simplify the management of routine tasks and accelerate operational efficiency.

Benefits of Optimizing Supply Chain

Optimizing your supply chain offers a host of benefits that can transform the way your business runs. It’s not just about trimming costs; it’s about enhancing performance, driving growth, and keeping customers happy.

1. Cost Reduction

One of the biggest reasons companies focus on optimization is to reduce costs. Supply chain network optimization helps streamline operations, lower transportation costs, and manage inventory more efficiently. By automating inventory tracking and reducing stock levels, businesses can cut down on storage and handling costs.

Tools like GoProcure can assist in securing better deals from suppliers, optimizing procurement and driving down prices. Optimizing every part of the supply chain means fewer delays, fewer errors, and fewer costs, allowing businesses to operate more profitably.

2. Faster Delivery Times

An optimized supply chain enables faster delivery. The more efficient your supply chain is, the quicker products can move from suppliers to customers. This means your company can meet customer expectations for timely deliveries, which builds loyalty and trust. With real-time tracking and better management of transportation routes, businesses can ensure products arrive on time, every time.

Supply chain visibility tools help ensure transparency across the process, providing key insights into delivery times and allowing companies to anticipate and prevent any delays. Faster deliveries often lead to higher customer satisfaction and repeat business.

3. Enhanced Customer Satisfaction

Optimizing your supply chain doesn’t just benefit your bottom line; it directly impacts your customers. By reducing lead times, improving inventory management, and ensuring timely deliveries, you’re creating a better experience for your customers. Happier customers are more likely to come back and recommend your services to others.

When supply chain visibility is improved, customers get real-time updates on their orders, which enhances their confidence in the company. Tools that offer automated tracking and delivery updates help keep customers informed, which increases overall satisfaction.

4. Risk Management and Flexibility

Supply chain optimization isn’t just about speed and cost; it also involves preparing for risks. Supply chain disruptions can happen, whether due to supplier delays, natural disasters, or unforeseen demand surges. Optimizing supply chain processes gives businesses the flexibility to adapt to these challenges quickly. With data-driven insights, businesses can foresee potential disruptions and make adjustments to their strategy on the fly.

By leveraging predictive analytics, companies can spot risk factors and mitigate them before they cause serious damage. Having visibility across the entire supply chain helps businesses stay proactive instead of reactive.

Challenges While Optimizing Supply Chain

While supply chain optimization offers many benefits, it’s not without its challenges. Here are some of the most common obstacles businesses face:

1. Data Integration and Accuracy

To truly optimize your supply chain, you need accurate, real-time data that is integrated across the entire process. Without it, you risk making decisions based on outdated or incomplete information.

Many businesses still struggle with data silos, where information is trapped in different systems, making it difficult to get a full picture of operations. To solve this, businesses need to invest in supply chain visibility tools that provide centralized data access, ensuring that everyone in the organization is working from the same information.

2. Supplier Relationships

Collaboration with suppliers is essential for optimization, but not all suppliers will be on the same page. Building strong, transparent relationships with suppliers helps improve coordination and reduces delays. But maintaining this level of communication can be challenging, especially if suppliers don’t have access to real-time data.

Using tools that enable supply chain collaboration can make a huge difference. For example, real-time demand forecasts shared with suppliers help them adjust production schedules in line with actual customer needs, which minimizes delays and stockouts.

3. Resistance to Change

Implementing new processes and tools can be met with resistance, particularly from employees or suppliers who are accustomed to old ways of doing things. Overcoming this challenge requires clear communication, ongoing training, and showing everyone how optimization will benefit the company as a whole. The key is to make the transition as smooth as possible and demonstrate the long-term value of optimization.

Also Read: Major Supply Chain Challenges Businesses Must Overcome

Best Practices for Supply Chain Optimization

To make the most of supply chain optimization, businesses need to adopt a few best practices. Here are some tried-and-tested methods:

1. Automate Repetitive Tasks

Automating routine tasks is one of the easiest ways to optimize your supply chain. Tasks like inventory management, order processing, and invoicing can all be automated, reducing the potential for human error and speeding up operations.

By automating these tasks, businesses can focus on higher-level decision-making and strategy. For instance, GoInvoice helps businesses automate invoicing, saving time and reducing errors. Automating your supply chain through tools like these can streamline operations and free up resources.

2. Optimize Inventory Management

One of the most important aspects of optimization is managing inventory efficiently. Businesses that don’t optimize their inventory risk carrying excess stock, which ties up capital and increases storage costs. On the other hand, poor inventory management can lead to stockouts and missed sales opportunities.

By using real-time data, businesses can maintain the right stock levels at the right time. Demand forecasting tools, powered by AI, can predict fluctuations in demand, ensuring businesses don’t overstock or understock products.

3. Leverage Technology

The right technology can make all the difference in optimizing your supply chain. From AI-powered predictive analytics to IoT-enabled tracking devices, embracing technology helps businesses improve efficiency and gain valuable insights into their operations.

Technologies like blockchain can provide transparency, reducing fraud and errors in the supply chain, while cloud-based SCM software enables businesses to access their supply chain data from anywhere, making real-time decision-making much easier.

How to Measure the Success of Supply Chain Optimization

Once you’ve implemented supply chain optimization strategies, it’s important to track how well they’re working. Here are some key performance indicators (KPIs) to monitor:

1. Inventory Turnover

Inventory turnover measures how often inventory is sold and replaced. A high turnover rate suggests that products are moving quickly, which is a sign of an efficient supply chain. Low turnover, however, could indicate overstocking or inefficiencies.

2. On-Time Delivery

On-time delivery is one of the most important metrics for supply chain success. If you’re delivering products on time, it shows that your supply chain visibility and operations are working smoothly. A high on-time delivery rate means customers are getting their orders when expected, leading to higher satisfaction.

3. Lead Time

Lead time is the total time it takes from receiving an order to delivering it to the customer. Shorter lead times indicate a well-optimized supply chain. Optimizing production, reducing delays, and improving communication can all contribute to shorter lead times.

Conclusion

Optimizing your supply chain isn’t just about reducing costs—it’s about creating a more efficient, responsive, and flexible operation that can meet customer demands and anticipate market changes. By investing in the right tools, adopting best practices, and maintaining strong relationships with suppliers, businesses can drive long-term success.

The benefits are clear: faster deliveries, better customer satisfaction, reduced costs, and increased operational efficiency. Supply chain optimization is the key to staying competitive in today’s fast-paced world, and with the right strategies and technologies, you’ll be in a great position to lead the way.

FAQs

What tools are available for supply chain optimization?

There are several supply chain optimization tools available, including inventory management systems, predictive analytics software, and real-time tracking tools. GoProcure and GoTrack provide businesses with real-time visibility into their supply chain, helping streamline operations.

How does supply chain optimization impact customer satisfaction?

Supply chain optimization improves customer satisfaction by ensuring timely deliveries, accurate order fulfillment, and better communication. When customers get their orders on time and without issues, they’re more likely to return and recommend your business.

What is the difference between supply chain optimization and supply chain management?

While supply chain management involves the overall process of managing the flow of goods and services, supply chain optimization focuses on improving the efficiency and effectiveness of each part of the supply chain. Optimization is about fine-tuning the existing supply chain to make it faster, cheaper, and more responsive.