Direct vs. Indirect Procurement – Key Differences, Strategies & Best Practices

Table of Contents

Procurement is the backbone of any business, but not all purchases are created equal. Direct and indirect procurement serve different functions, impact operations in unique ways, and require distinct strategies. Getting them right can help businesses save costs, strengthen supplier relationships, and streamline processes.

With the growing use of digital procurement strategies and procurement analytics, companies are now making more informed purchasing decisions than ever. Let’s dive in.

What Is Direct Procurement? Definition & Examples

Direct procurement involves purchasing goods and services that are directly tied to a company’s core products. These are non-negotiable for operations and have a direct impact on the supply chain.

Examples:

- Raw materials for manufacturing

- Components for product assembly

- Machinery and production equipment

- Inventory for retail businesses

Since direct procurement affects everything from production schedules to delivery timelines, businesses invest heavily in supplier relationships, quality control, and logistics management. Many are also leveraging procurement analytics to track supplier performance and optimize costs.

What Is Indirect Procurement? Definition & Examples

Indirect procurement covers purchases that support business operations but are not directly linked to the production of goods or services. These expenses keep the organization running but don’t directly contribute to revenue generation.

Examples:

- Office supplies and equipment

- IT services and software

- Marketing and advertising

- Facility management

Since indirect procurement often involves various departments, costs can become difficult to control. Many businesses are turning to digital procurement transformation to improve visibility and manage indirect spending more efficiently.

Key Differences Between Direct and Indirect Procurement

Both direct and indirect procurement are essential, but they function differently in terms of impact, cost management, and supplier relationships.

Impact on Supply Chain and Operations

- Direct procurement is closely tied to production schedules, inventory levels, and supply chain continuity. A delay in direct procurement can halt production and disrupt customer deliveries.

- Indirect procurement affects internal operations and employee productivity but doesn’t immediately impact product availability.

Cost Implications and Budgeting Differences

- Direct procurement costs are planned in advance and aligned with production needs.

- Indirect procurement costs tend to be more variable and spread across multiple departments. Businesses using procure-to-pay software gain better control over these expenses through automated approvals and budgeting tools.

Supplier Relationship Management: How It Differs

- Direct procurement suppliers require long-term contracts and strong partnerships to ensure a reliable supply chain.

- Indirect procurement suppliers are often chosen based on cost, convenience, and service quality. Organizations that use centralized procurement models often have better supplier oversight, while decentralized procurement allows for greater departmental flexibility.

Challenges in Managing Direct and Indirect Procurement

Procurement isn’t always smooth sailing. Each type comes with its own set of challenges that businesses must address.

Direct Procurement Challenges

- Supplier reliability: Disruptions in supply can bring production to a standstill.

- Cost fluctuations: Raw material prices can change due to market conditions, making budgeting tricky.

- Quality control: A single defective component can lead to recalls and production delays.

- Risk management: Factors like geopolitical instability and transportation delays can create unexpected hurdles.

Indirect Procurement Challenges

- Lack of visibility: Purchases are often made across departments without a centralized tracking system.

- Maverick spending: Unapproved purchases can lead to budget overruns.

- Contract inefficiencies: Without standardized agreements, businesses may end up overpaying or receiving inconsistent service.

- Unnecessary expenses: Poor tracking and control can result in excessive or redundant purchases.

Many companies are addressing these issues by leveraging procurement analytics to improve visibility, optimize costs, and make data-driven decisions.

Best Strategies for Managing Direct and Indirect Procurement

How to Optimize Direct Procurement Processes

- Establish long-term contracts with key suppliers.

- Use demand forecasting to avoid overstocking or shortages.

- Adopt procurement automation tools to streamline ordering, tracking, and supplier collaboration.

Best Practices for Indirect Procurement Cost Control

- Consolidate vendors to negotiate better pricing and improve efficiency.

- Implement strict budget controls and approval workflows.

- Utilize spend analytics to identify cost-saving opportunities.

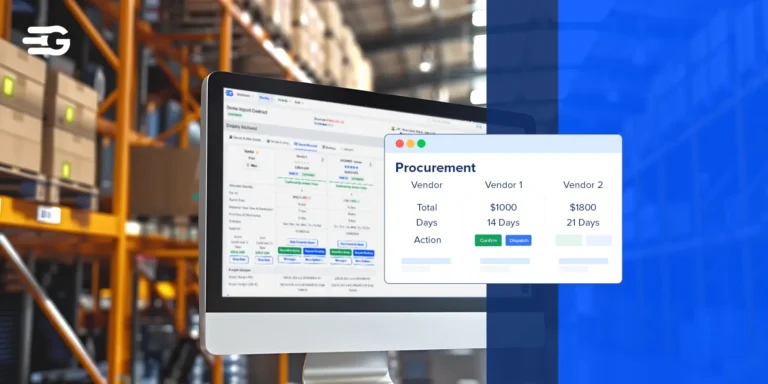

The Role of Automation and Procurement Technology

- E-procurement platforms enhance transparency and streamline workflows.

- AI-driven analytics help businesses select better suppliers and optimize negotiations.

- Automation tools reduce manual workload, improving speed and accuracy.

How Technology Is Changing Procurement – Trends & Innovations

The Rise of AI & Automation in Procurement

AI is changing the procurement game by automating repetitive tasks, improving demand forecasting, and enhancing supplier evaluations. AI-driven procurement analytics can also predict risks and optimize contract terms. Businesses integrating AI-driven procurement analytics are gaining a competitive edge in cost management and efficiency.

Data-Driven Decision-Making for Procurement Professionals

With advanced analytics, businesses can track spending patterns, assess supplier performance, and make procurement decisions backed by real-time data. Those embracing digital procurement strategies are seeing increased operational efficiency and reduced costs.

Final Words

Direct and indirect procurement require different management approaches, but both play a crucial role in business success. Companies that embrace automation, strong supplier relationships, and cost control strategies will be better positioned for efficiency and growth.

With digital procurement technologies and AI-driven analytics, procurement is becoming smarter, more strategic, and more cost-effective. Optimizing procurement isn’t just about reducing costs. It’s about creating a streamlined, data-driven, and future-ready business.