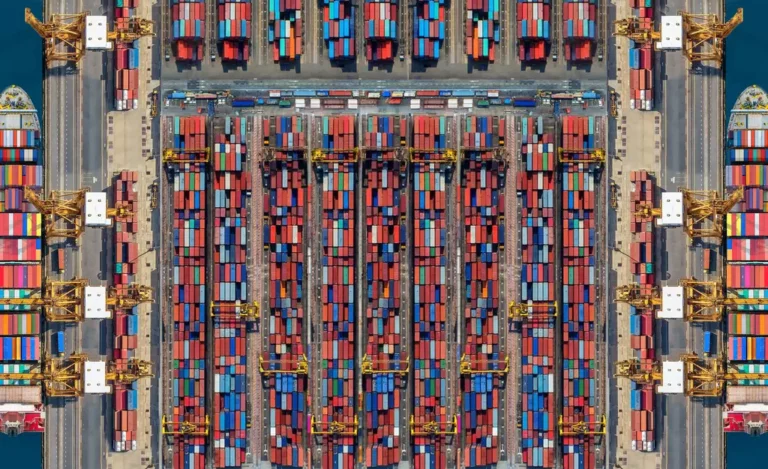

What Are Online Container Tracking Systems?

Online container tracking systems are software platforms designed to provide real-time visibility into the location and status of shipping containers. These tools continuously update users on container position, key transportation milestones, and condition monitoring from origin to destination. For logistics professionals, such systems are essential for proactive decision-making and streamlined operations.

How Container Tracking Systems Work

These systems function by collecting, integrating, and analyzing data from multiple points across the supply chain. Here’s how they operate:

Data Collection Methods

Technologies such as Global Positioning System (GPS), Automatic Identification System (AIS), Radio Frequency Identification (RFID), and Internet of Things (IoT) sensors gather location and environmental data from containers, ensuring accuracy throughout multimodal transit.

Data Integration

Information is aggregated from carriers, port terminals, customs, AIS feeds, and third-party APIs into a centralized platform, enabling a unified operational view.

Data Processing & Analytics

Using machine learning and big data, advanced systems forecast estimated times of arrival (ETAs), detect anomalies, and anticipate disruptions, empowering users to act preemptively.

Essential Features of Online Container Tracking

To evaluate a tracking system effectively, consider its key capabilities:

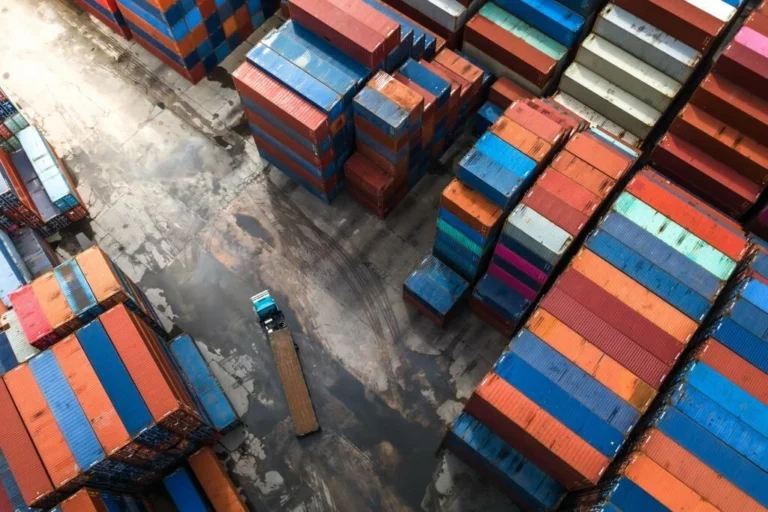

Real-Time Tracking & Geolocation

Live maps and geotagging let users pinpoint containers globally, whether at sea or in intermodal transit.

Alerts and Notifications

Automated updates notify users when containers hit milestones or encounter exceptions like delays.

Carrier & Terminal Visibility

Access detailed data including port-specific ETAs, cutoff times, and container yard status.

Multimodal & API Integration

Track shipments across sea, rail, and road, with seamless API connections to TMS and ERP systems.

IoT-Based Condition Monitoring

Monitor conditions like temperature, humidity, vibration, and shock to ensure cargo integrity, especially for sensitive goods.

Security Features

Tools like geofencing and tamper alerts help prevent unauthorized access and mitigate risks.

Benefits of Online Container Tracking

Implementing a robust tracking system delivers tangible operational advantages:

Operational Efficiency & Cost Reduction

Real-time visibility improves planning and reduces costly issues like demurrage and detention.

Risk Mitigation

Continuous monitoring enables early detection of disruptions and timely intervention.

Improved Customer Communication

Reliable updates enhance service transparency and foster stronger client relationships.

Use Cases & Who Benefits

These systems support a broad range of logistics professionals:

Freight forwarders, 3PLs, importers/exporters, and internal logistics teams all benefit from real-time visibility. GoComet clients, for instance, have significantly reduced demurrage fees through better container tracking.

Choosing the Right System

Before investing in a container tracking solution, assess the following:

Feature Checklist

Ensure the system includes precise tracking, broad carrier coverage, API integration, IoT support, and security protocols.

Integration & Ease of Use

Select platforms that work well with existing systems and offer a user-friendly interface.

Pricing & Trials

Look for flexible pricing plans and trial options. GoComet provides scalable packages tailored to shipment volume and operational complexity.

Conclusion

Online container tracking systems are now fundamental to modern logistics. By combining live tracking, environmental monitoring, and predictive analytics, these platforms help organizations optimize supply chains, reduce delays, and improve customer experience. Understanding the core functions and choosing the right solution can transform the way your business manages international shipments.