MS vs Freight Management Systems: What’s right for you?

Freight operations have come a long way from the days when everything ran on phone calls, spreadsheets, and crossed fingers. Back then, tracking a shipment meant calling three different people just to get a “maybe it’s somewhere near Chicago” update. Today’s supply chains are more complex, faster, and frankly, less forgiving of those old-school methods.

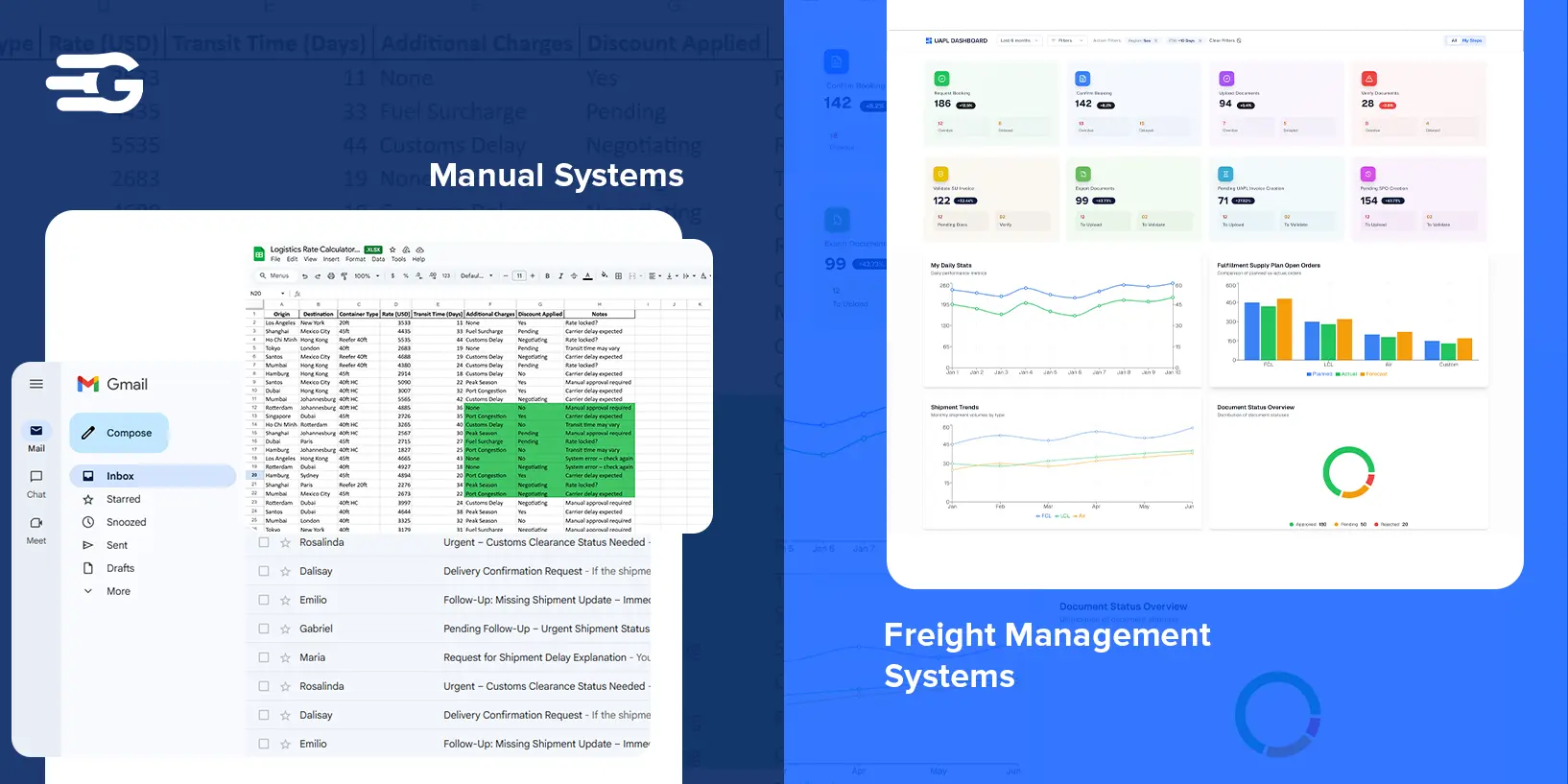

The thing is, many businesses still find themselves caught between two worlds. On one side, you have manual systems (MS) that feel familiar but drain resources. On the other, there are freight management systems promising efficiency but requiring investment. Let’s see how they stack up against each other.

What Are Manual Systems (MS)?

Manual systems in freight management are exactly what they sound like – the traditional way of handling logistics through direct human intervention. Think emails flying back and forth between carriers, Excel spreadsheets tracking shipments, and phone calls to check where that container actually is right now.

These approaches rely heavily on people manually inputting data, making decisions, and coordinating between different parties in the supply chain.

Here’s what MS vs Freight Management systems looks like when you’re running manual operations:

- Communication Chaos: Every update requires someone to pick up the phone or send an email. Rate negotiations happen through lengthy email chains, shipment updates get lost in inboxes, and critical information often sits with one person who might be out sick that day.

- Spreadsheet Overload: One wrong cell entry can throw off entire reports, and version control becomes a nightmare when multiple people need access to the same data. With manual data entry producing 10-40 times more errors than automated systems, these mistakes compound quickly across large freight operations.

- Reactive Problem Solving: Issues only surface when someone notices them – like when a customer calls asking where their shipment is, or when an invoice doesn’t match what was expected. There’s no early warning system, just constant firefighting.

The reality is that manual systems worked fine when freight volumes were lower and customer expectations were different. But the current logistics environment demands speed and accuracy that human-only processes simply can’t deliver consistently.

When comparing MS vs Freight Management systems, the limitations become pretty obvious once you scale beyond a certain point.

What Is a Freight Management System (FMS)?

A Freight Management System is software that handles the heavy lifting of logistics operations automatically. Instead of juggling multiple spreadsheets and phone calls, an FMS centralizes everything – from carrier selection to shipment tracking to invoice processing.

It’s like having a digital logistics coordinator that never sleeps, never forgets details, and can handle thousands of shipments simultaneously without breaking a sweat.

Modern platforms like GoComet take this concept further by adding AI-powered features that actually learn from your shipping patterns. The system can predict delays before they happen, benchmark freight rates across multiple carriers in real-time, and provide predictive ETAs that customers can actually rely on.

Consider how a global pharmaceutical company with 14 manufacturing facilities was bogged down by freight invoice verification errors across hundreds of monthly shipments. GoComet’s freight management platform automated their entire invoice reconciliation process, transforming their logistics team’s productivity from manual error-hunting to strategic freight optimization.

MS vs FMS: Key Differences

The gap between manual systems and freight management platforms becomes obvious once you look at day-to-day operations.

While manual processes might feel more hands-on, they create bottlenecks that modern supply chains simply can’t afford. The comparison between MS vs Freight Management systems shows how technology changes basic logistics functions into strategic advantages.

| Aspect | Manual Systems (MS) | Freight Management Systems (FMS) |

| Visibility | Limited to what people remember to update | Real-time tracking across entire supply chain |

| Data Accuracy | Prone to human error, inconsistent formats | Automated data capture with validation rules |

| Decision Speed | Hours or days for rate comparisons | Instant carrier benchmarking and selection |

| Scalability | Requires more staff for higher volumes | Handles increased volume without additional headcount |

| Cost Control | Reactive invoice checking, manual audits | Proactive cost monitoring with automated alerts |

| Communication | Phone calls, emails, scattered updates | Centralized platform with automated notifications |

What really sets modern freight management apart is predictive capability. While manual systems are always playing catch-up, reacting to problems after they occur, advanced FMS solutions can spot potential issues before they impact your supply chain.

When evaluating MS vs Freight Management systems, this shift from reactive to proactive operations often justifies the investment on its own.

Benefits of Adopting a System Like GoComet

Moving from manual processes to a comprehensive freight management platform creates immediate operational improvements that your team will notice from day one. GoComet’s approach to freight management goes beyond basic digitization – it transforms how your logistics operation functions at every level.

The shift from MS vs Freight Management systems becomes most apparent when you see how much time your team gets back for strategic work instead of administrative tasks.

The business impact shows up in multiple areas:

- Real-Time Intelligence That Actually Works: GoComet’s platform provides live shipment tracking and predictive ETAs that you can share confidently with customers. No more “let me check and get back to you” responses. The system pulls data directly from carriers and ports, giving you visibility that manual tracking simply can’t match.

- Automated Rate Benchmarking: Instead of spending hours calling different carriers for quotes, GoComet’s AI analyzes market rates and suggests the best options based on your specific requirements. The platform learns from your shipping patterns and preferences, making recommendations that improve over time.

- Centralized Communication Hub: All stakeholder communication happens in one place, with automated updates sent to relevant parties when shipment status changes. This eliminates the endless email chains and missed phone calls that plague manual systems.

- Data-Driven Cost Optimization: The platform identifies spending patterns and highlights opportunities for savings that might not be obvious when you’re managing everything manually.

When companies make the transition from MS vs Freight Management systems using platforms like GoComet, the most common feedback is how much clearer everything becomes.

Decisions that used to require multiple meetings and phone calls can now be made quickly with confidence, backed by real data instead of best guesses.

When to Transition to a Freight Management System

The right time to move from manual processes isn’t always obvious, but certain warning signs make it clear that your current approach is holding back growth.

Most companies reach this point when their logistics team spends more time hunting for information than actually managing freight strategy.

These key signals indicate it’s time to make the switch:

- Your team constantly plays logistics detective – If finding shipment status requires multiple phone calls and emails, you’re wasting valuable time that could be spent on cost optimization and carrier relationship management.

- Customer inquiries outpace your visibility – If customers know more about shipping delays than your logistics team does, your tracking capabilities aren’t keeping pace with expectations.

- Growth plans stall due to operational limits – When adding more shipment volume means hiring more people just to handle administrative tasks, you’ve hit the scalability wall that defines the MS vs Freight Management systems decision point.

- Invoice errors are eating into margins – When freight invoice discrepancies become a weekly headache rather than an occasional issue, manual verification processes are costing more than the technology investment.

The decision between MS vs Freight Management systems often comes down to whether your current processes can scale with your business ambitions.

Modern freight management platforms like GoComet scale these operations naturally with business growth. Instead of adding headcount every time shipping volume increases, the system handles more complexity without breaking a sweat. When your freight operations become a competitive advantage rather than just a cost center, you’ll know the transition was worth it.

Conclusion

The choice between MS vs Freight Management systems comes down to whether you want your logistics operation to keep up or lead the way. Manual systems might feel comfortable for smaller operations, but they quickly become bottlenecks as business grows.

Modern freight management platforms like GoComet digitize your processes to transform how your entire supply chain operates. If you’re curious about how this might work for your specific setup, GoComet offers demos to walk through real scenarios.

![[Complete Guide] What is Visible Supply Chain Fulfillment? 5 [Complete Guide] What is Visible Supply Chain Fulfillment?](https://www.gocomet.com/blog/wp-content/uploads/2025/04/Supply-Chain-Examples-An-Ultimate-List-to-Learn-From-768x384.webp)