Why Most TMS Platforms Fail to Deliver Real-Time Visibility

You know that feeling when a critical shipment just disappears? One minute you’re tracking everything, the next you’re staring at a screen with no updates for hours. That’s the reality behind TMS real-time visibility issues hitting operations everywhere. Real-time visibility should mean live data on every shipment, every moment. Not yesterday’s batch update or some carrier’s best guess.

Most TMS platforms promise this visibility but deliver something more like “mostly real-time when things go well.” Over 50% of companies lack end-to-end supply chain visibility, forcing them into reactive mode. Each handoff creates another blind spot where TMS real-time visibility issues turn routine shipments into emergencies.

With that said, let’s look at why most TMS platforms fail to deliver the visibility your operations actually need.

Pitfall #1: Reliance on Batch Data Updates

Here’s where most TMS platforms show their age. They still operate like it’s 2010, pulling data in chunks rather than streaming it live.

Most TMS platforms still pull data in chunks instead of streaming it live. Your system updates carrier information once hourly or at day’s end while shipments sit in limbo. These TMS real-time visibility issues come from legacy systems treating data like scheduled mail runs rather than continuous conversations.

- Batch processing creates operational blind spots. When updates only happen overnight or hourly, problems develop and persist without detection. A detention situation or route deviation occurs but won’t show in your system until the next data sync.

- Delayed exception alerts kill response time. Critical notifications arrive after meaningful action becomes impossible. The missed pickup alert reaches you hours after the window closed. Your team spends time chasing information instead of solving problems.

- Historical data doesn’t support proactive decisions. Batch systems show you what happened, not what’s happening. This forces reactive management instead of getting ahead of issues before they impact operations.

This approach turns transportation management into constant firefighting. TMS real-time visibility issues multiply when your data foundation operates on yesterday’s schedule while your business runs on today’s demands.

Pitfall #2: Fragmented Systems and Data Silos

Walk into most logistics operations and you’ll find a patchwork of systems that don’t talk to each other. One carrier portal for FedEx, another for UPS, spreadsheets for regional carriers, plus your ERP pulling its own data.

Each system holds pieces of the puzzle, but nobody sees the complete picture. These TMS real-time visibility issues multiply when critical information sits trapped in separate platforms.

| System Type | What It Tracks | The Problem |

| Carrier Portals | Individual carrier data | Requires manual checking across multiple sites |

| ERP Systems | Order and inventory data | No connection to actual shipment movement |

| Spreadsheets | Regional carrier info | Manual updates, prone to errors |

| Legacy TMS | Some integrated carriers | Limited coverage, outdated connections |

Partial insights lead to poor decisions. When you can only see 60% of your shipments in real-time, the other 40% become guesswork. You’re making routing and scheduling decisions based on incomplete information.

This fragmentation forces logistics teams to become data detectives instead of strategic planners. TMS real-time visibility issues persist when your technology stack works against unified operations rather than supporting them.

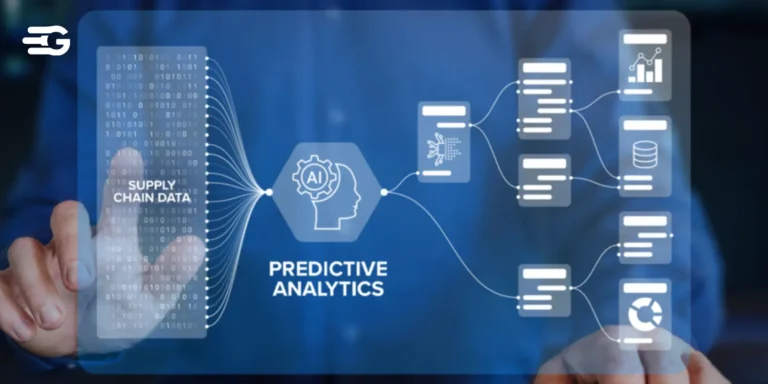

Pitfall #3: Lack of Predictive Analytics

Knowing where your shipment is right now only tells half the story. Most TMS platforms excel at reporting current location but fail miserably at predicting what happens next.

They’ll show you a truck sitting in Dallas but can’t tell you if it’ll make the delivery window in Houston.

These TMS real-time visibility issues stem from systems that track location without understanding the bigger operational picture.

- Location data without ETA intelligence creates false confidence. Your shipment shows “in transit” but weather patterns, traffic conditions, and driver hours-of-service rules all impact actual arrival times. Static ETAs based on original schedules become meaningless when reality intervenes.

- Historical patterns remain unused for forecasting. Your TMS sits on months of carrier performance data but can’t apply those insights to predict future issues. Route-specific delays, seasonal patterns, and carrier reliability trends stay buried in reports instead of powering proactive alerts.

Without predictive capabilities, you’re managing transportation through the rearview mirror. TMS real-time visibility issues persist when your system only reports the present without preparing you for what’s coming next.

For example, one global chemical distributor with 200+ monthly international shipments discovered this gap during recent port congestion. Without predictive capabilities, they couldn’t anticipate which deliveries would be affected until delays had already cascaded through their operations.

GoComet’s predictive analytics helped them shift from reactive crisis management to proactive planning, providing early warnings that let them communicate with customers before problems became emergencies.

Pitfall #4: Limited Carrier Network Coverage

Many TMS platforms only integrate with major national carriers, leaving regional and specialized providers in a connectivity desert. Your platform might track FedEx and UPS perfectly but go completely dark when shipments transfer to local delivery services or specialized freight carriers.

These TMS real-time visibility issues become critical when your carrier network operates outside your system’s reach. The coverage gap forces manual workarounds that defeat the purpose of automation. You end up calling regional carriers for updates or simply hoping everything goes according to plan.

When a shipment moves from your integrated carrier to an unconnected regional partner, visibility vanishes at the handoff point. TMS real-time visibility issues compound because these smaller carriers often handle the most challenging delivery scenarios where real-time updates matter most.

Pitfall #5: Poor User Experience & Alert Fatigue

Even platforms with decent data often bury it under terrible interfaces and notification spam. Your team gets 47 alerts about routine status updates but misses the one critical exception that needs immediate attention.

Complex dashboards require three clicks to find basic shipment information while urgent alerts get lost in a sea of routine notifications. These TMS real-time visibility issues turn information overload into operational blindness.

| Alert Type | Frequency | Actual Importance | Result |

| Routine pickups | 15-20 per day | Low | Noise that masks critical issues |

| Status updates | 30+ per day | Minimal | Creates alert fatigue |

| True exceptions | 1-2 per day | Critical | Gets buried in notification flood |

| System maintenance | Weekly | None | Adds to the clutter |

Teams start ignoring alerts entirely because the signal-to-noise ratio becomes unbearable. Your operations manager stops checking notifications because 90% are meaningless status updates.

When a real crisis hits, it looks identical to routine noise.

TMS real-time visibility issues multiply when poor UX design makes critical information inaccessible exactly when you need it most.

How GoComet Delivers True Real-Time Visibility

GoComet built its platform specifically to solve the TMS real-time visibility issues that plague traditional systems.

Instead of retrofitting old architecture, we designed streaming data connections from the ground up. Our platform treats real-time visibility as the foundation, not an afterthought, connecting directly with over 200 carriers and IoT devices for continuous data flow.

- AI-powered ETA calculations. Our system analyzes traffic patterns, weather conditions, driver behavior, and historical performance to calculate realistic arrival times. You get early warnings about potential delays while there’s still time to take action.

- Streaming API integrations eliminate data delays. Direct connections with carriers and tracking devices push updates instantly instead of waiting for batch processing. When a truck stops, reroutes, or encounters delays, your dashboard reflects the change within minutes, not hours.

- Unified dashboard. Operations managers see high-level fleet status while dispatchers get detailed route information. Configurable alerts ensure critical exceptions reach the right people without overwhelming anyone with irrelevant notifications.

- Mobile-first design supports field operations. Drivers and field personnel can update status, report issues, and communicate directly through the platform, keeping data current from every touchpoint.

This approach transforms TMS real-time visibility issues from constant frustration into competitive advantage, giving your team the information and tools needed for proactive transportation management.

Conclusion

Most TMS platforms promise real-time visibility but deliver something closer to “eventually visible.” The reality is batch updates, disconnected systems, and alert overload that turns your logistics team into firefighters instead of strategic planners. These TMS real-time visibility issues aren’t going away with patches or workarounds.

Your operations need platforms that actually work the way modern logistics moves. Continuous data streams, unified carrier networks, and smart alerts that help you stay ahead of problems instead of chasing them. TMS real-time visibility issues become competitive disadvantages when everyone else is operating with better information.

Book a demo with GoComet see what actual real-time visibility looks like.